Additive manufacturing comes of age

From space rockets to bionic arms, gearboxes to housing complexes, 3D printing is going mainstream. Alex Eliseev explores what’s next for this transformative technology

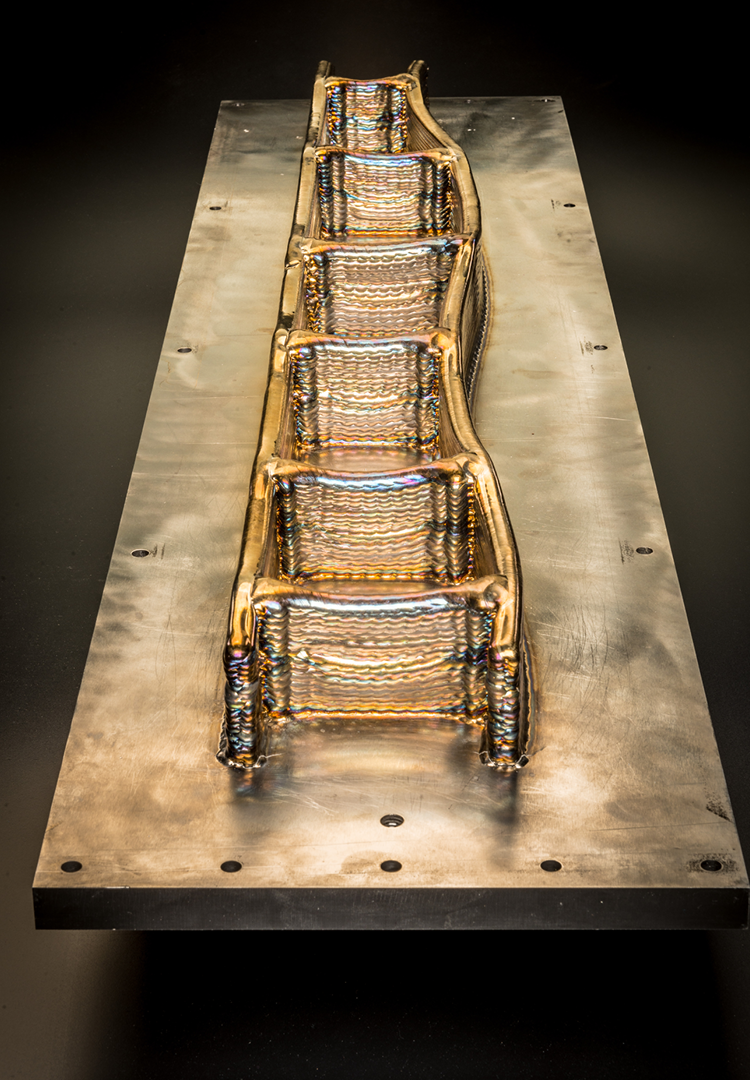

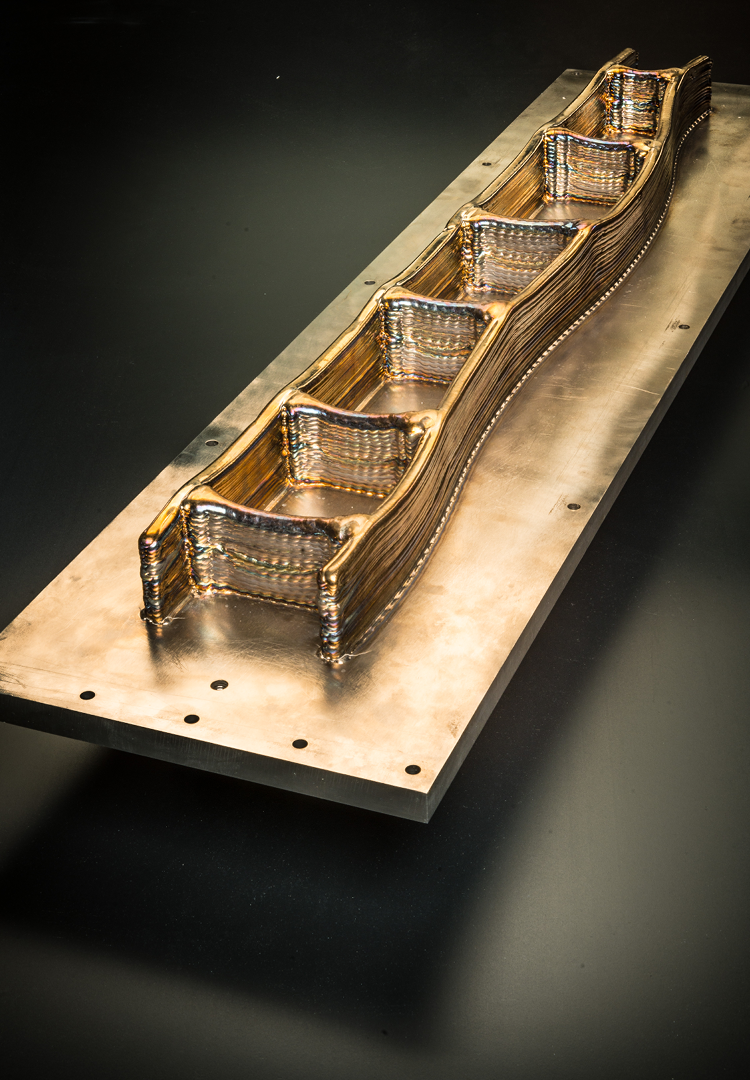

Five years ago, Filomeno Martina was a senior lecturer at Cranfield University, teaching additive manufacturing. Today he’s the founder and CEO of a company that sells 3D printing machines, components, custom software and even some metal alloys. Specialising in wire arc additive manufacturing, the company’s machines are used around the planet by clients in industries such as aerospace, energy and mining. The parts they create can now be measured in metres, not just centimetres.

Wearing a black sweatshirt, his hair tied back, Martina walks over to one of his flagship RoboWAAM printers. It looks big enough to drive a car into. His attention flicks to a stack of large wooden boxes on the factory floor. “These are a couple of machines being built for customers,” he says, a smile spreading across his bearded face. “One in Canada and one in Japan. It’s exciting times here!”

Martina’s start-up firm, WAAM3D, was included in a list of 10 most innovative 3D printing companies last year, while he was awarded an International Outstanding Young Researcher prize. The company (a Cranfield University spin-off) employs around 30 people, has a joint-venture partner in Singapore and expects up to 700% better performance from its next-generation printer.

“I’ve had a feeling that additive manufacturing was on the cusp… that something massive was coming… every day of my life for the last 10 years,” explains Martina. “You keep moving the goalpost, asking, ‘what’s next?’. You keep growing, you keep accelerating. Now, I think we are there.”

‘The things that have been made with additive manufacturing are incredible. And they are only going to get more incredible’

Ready for stardom

Global consulting firm McKinsey agrees. “After decades as a bit player, additive manufacturing is on the cusp of stardom,” it said in a recent report.

So does manufacturing platform Hubs, which predicts that the global 3D printing market will grow by 17% this year, to reach just short of $20bn. Hubs has previously forecast that the industry will almost triple by 2026, reaching $44.5bn.

“The technology is now maturing and realising its industrial potential,” reads its 3D Printing Trend Report 2023. “Its evolution from a hobbyist technology to an industrial manufacturing solution is only gaining momentum.”

It may have started out as science fiction back in the 1940s, but modern additive manufacturing has been commercially successful for years. From hearing aids to teeth aligners, from shoes to aircraft parts, it’s made its way into our lives.

There are various 3D printing techniques. Some use raw material powders, others use wires. Some heat materials with lasers, others with electric arcs or beams. Some build up layers, others extrude materials (like squeezing toothpaste). Each has its own strengths and weaknesses, and some are more advanced than others. But the core idea is to build up objects layer by layer, as opposed to carving them from a larger chunk.

After the hype, a busy decade

Richard Hague, a professor of additive manufacturing at the University of Nottingham, has been involved with the technology for 30 years. He’s a co-founder of two additive manufacturing spin-off companies, Added Scientific and Reactive Fusion. Like Martina, he’s got a passion for “taking our work out of the lab into the wide world”.

Hague says much of the earlier hype about additive manufacturing was the result of low-cost printers flooding the market. While today people may not be printing food or sneakers at home, he says, the hype did help march the technology into boardrooms.

“The mistake people made is thinking that additive manufacturing would take over everything. It won’t. It’s a tool in the toolbox,” Hague explains. “The primary reasons to implement it is to create complexity in a part, or to combine components. The key is to use it where its appropriate.”

With the right levels of interest and investment, it’s been a busy decade for additive manufacturing. There’s no single answer for what’s propelled it from an emerging technology to a mature one. It’s taken layers of innovation, new technologies and materials, and fast-flowing ripples of geopolitical change.

Innovation on all fronts

Jörg Bromberger, director of strategy for McKinsey’s Manufacturing and Supply Chain Practice, says much of the growth in the market is coming from new entrants. These new players offer new technology, new platforms and, crucially, new business models.

“There have been major evolutions in technology,” Bromberger explains. “Machines are performing better, there’s a wider range of materials available and the overall systems are getting faster. Companies have also expanded their service portfolios, moving beyond just selling machines or using someone else’s machines to produce parts.”

Manufacturing company VulcanForms is often cited as an example of a modern business model. It helps customers pick parts, design them and prepare them for printing. Then it manufactures the products. In Bromberger’s words, it “closes the loop on the entire value chain,” an emerging trend in the industry.

According to Hubs, smarter software is also driving the technology, along with improvements in industrial automation. Add to that concerns about global supply chains, availability of raw material supplies and political instability, and the power to create parts or prototypes locally (faster and cheaper too) writes its own business case.

Martina says some of his clients are interested in using additive manufacturing to repair valuable parts. Others want to be able to create highly customised, intricate parts at scale.

And all that before you get to the arrival of artificial intelligence.

This changes everything

It’s still early days, but some of the key areas where AI can transform 3D printing are emerging. One is quality control – the power to spot defects before it’s too late. Another is design, not only to help users create the most effective models, with the least amount of raw material, but also to open up the technology to more people (in the same way anyone can now ask ChatGPT to write complex computer code).

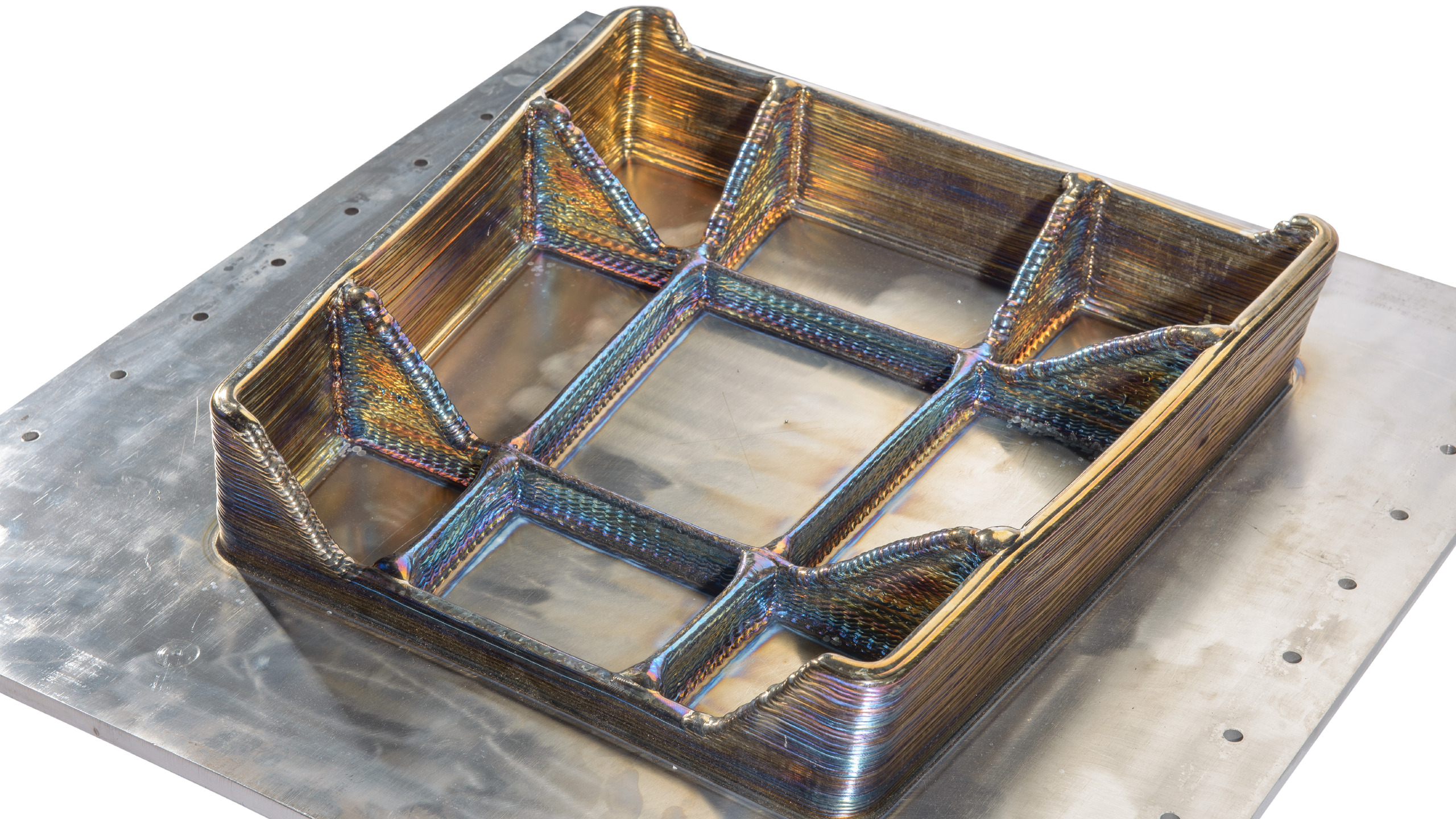

Some companies are already doing this. Los Angeles-based carmaker Czinger uses 3D-printed parts to assemble its $2m hypercar, the 21C. These parts are designed using what it calls its Divergent Adaptive Production System, which relies on AI to help optimise component design. In March, the company added a new gearbox case – a mission-critical part for a car that can hit 250mph – to its list of 3D-printed parts.

Generative design was recently used to create one of the largest-ever jet engine components, which contained more than 100 individual parts.

As Hubs explains, AI could also help optimise the production process itself, making it more stable and consistent. It might manage the meticulous fine-tuning of parameters (things such as layer height, density or path plans) and even guide the way future build rooms are configured.

From building objects to building systems

Hague believes AI can also play a role in additive manufacturing’s next chapter: functionality. It could help analyse and control the production of functional biological, electronic or pharmaceutical parts and systems.

“Additive manufacturing is an inherently digital process,” says Hague. “We’re not going to escape AI and machine learning.”

3D printing still has its limitations, relating to consistent quality, hardware, software and materials. Generally, affordability goes down as the size of a part goes up. And regulatory hurdles – particularly for critical, life-or-death components – are incredibly high. But, as Martina puts it, the conversations have moved far beyond “can this be done?”.

The examples are everywhere. Two young Ukrainian soldiers, who were wounded by landmines, recently received 3D-printed prosthetic arms, created by UK company Open Bionics, in partnership with a charity working in the war-torn country.

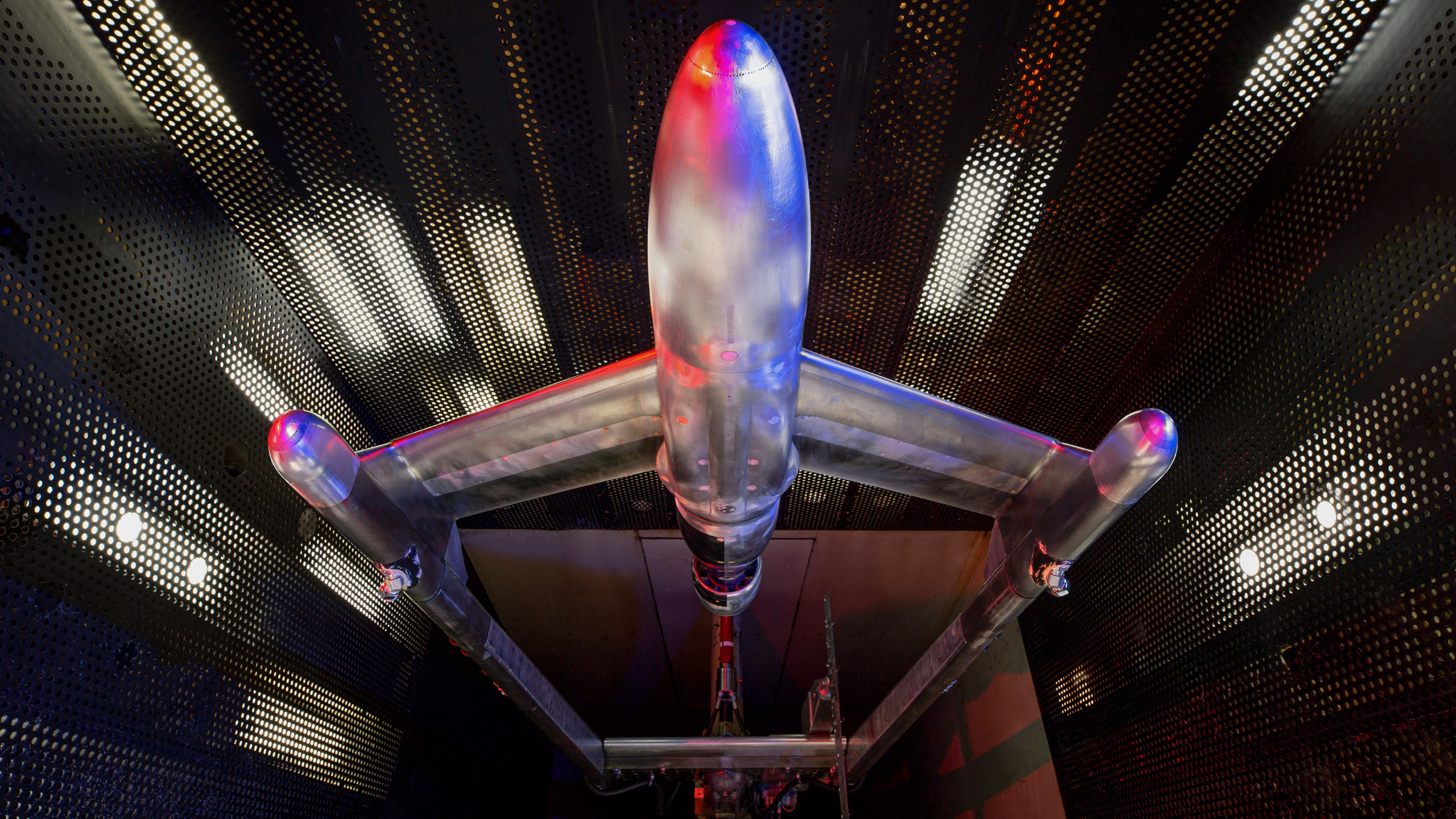

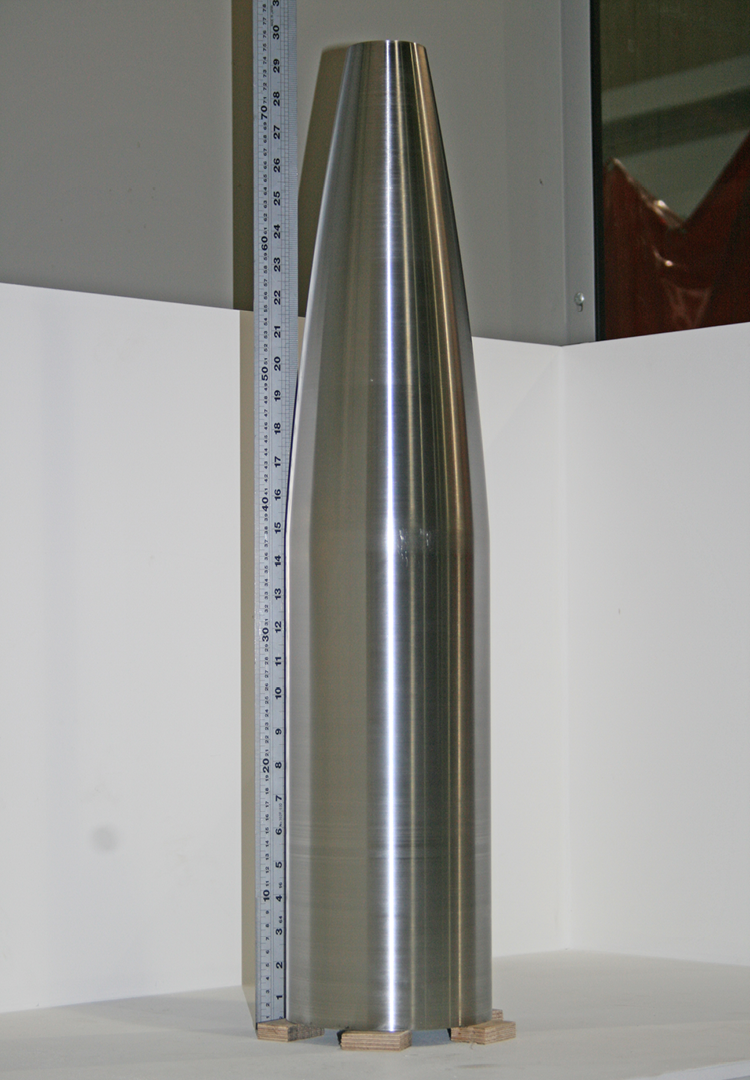

In March, in Florida, Relativity Space launched the “world’s first 3D-printed rocket” into space. The rocket, Terran 1, failed to reach orbit, but proved that printed material can withstand some of the most ferocious forces humans can throw at it. Standing 33m tall, the rocket was built using the world’s largest, custom-built 3D printer. Around 85% of it was made using additive manufacturing.

And in the UK, near Manchester, plans are under way to 3D print a 46-house complex. Building for Humanity says that when completed, hopefully this year, it will become the largest printed building complex in Europe, serving low-income families and military veterans.

The dance of a laser

Away from the headlines, companies are printing millions of components – everything from orthopaedic implants to fuel injector heads. Manufacturers are creating lighter, more intricate parts, in a fraction of the time. Others find value in printing prototypes or fixtures for existing machines.

For some experts, additive manufacturing is not going mainstream. It already is mainstream.

Sualp Ozel, a Fusion 360 senior product manager at software company Autodesk, is one such expert.

“Increasingly, most of the companies I interact with either have access to additive manufacturing hardware at their facility, or work with other manufacturers with access to it,” says Ozel. “Over the past five years, the cost of ownership and operation of those printers has decreased significantly, while the quality and reliability has improved. Now, organisations often have access to multiple systems with different 3D printing technologies. The software needed to drive those printers has also become more accessible and professional.”

The way the technology has evolved continues to capture the imaginations of those in the industry and those looking in. Hague says that, even after three decades, he’s still enchanted when he watches “a laser dance over a puddle of photo-curable material and turn it into a solid”.

“In the future, we will be able to make things that we can’t make today. We will add complexity in terms of geometry and functionality,” he says. “The opportunities for engineers are absolutely huge. If you like design, additive manufacturing will give you more freedom to create than any other manufacturing technique.”

New dimensions and frontiers

Autodesk’s Ozel says design is one of the main challenges for additive manufacturing. Engineers aren’t graduating with “explicit knowledge about design for additive manufacturing”. It’s a gap his company is trying to fill with various software solutions, which include generative design.

“Companies that promote a project-based learning culture and encourage their employees to experiment will be more successful with this technology,” says Ozel. In its report, McKinsey suggests companies start what it calls a centre of competence – a unit focused on experimenting, sharing knowledge and building skills.

Looking further ahead, Hague expects the technology to move into a realm of blended materials and entire 3D-printed systems. Imagine pills or implants that release different medicines at different times, complex scaffolding for growing human cells or innovative new generations of batteries and motors.

The Hubs report talks about 4D printing, with the fourth dimension being time. Responsive materials, fused into shape-morphing systems, would be able to change shape as they reacted to elements like heat, light or moisture. The applications would be endless, from implants that adapt to a patient’s body over time to self-assembling furniture or a coat that becomes thicker as the mercury drops.

“The things that have been made with additive manufacturing are incredible,” says Hague. “And they are only going to get more incredible.”

The journey is just beginning

Martina’s advice to engineers is to work at using additive manufacturing to design original, primary structures (“blockbuster applications”, as McKinsey frames it, not just spares or support components). Engineers, says Martina, have to understand a part’s purpose, to explore materials and weigh up things such as size and complexity to pick the right manufacturing technology.

“We are witnessing a growing amount of exploitation,” he concludes. “And we’ve barely scratched the surface of what additive manufacturing can do.”

The benefits of AM

The latest Hubs additive manufacturing industry report is packed with insights. It explores the market and latest trends and looks to the future. It unpacks how additive manufacturing is being used today, and which industries are using it most (spoiler: it’s aerospace, automotive and medical). It also looks at why the technology is better for our planet. This list (which we’ve summarised and paraphrased) is from that report.

1. Less waste: Manufacturers use only the material they need, and what they don’t use they can often save for the next print job. Smart software, used in design and to make sure there’s fewer failed builds, is helping to keep waste levels down.

2. Local production: Creating parts locally means less transport logistics and a smaller carbon footprint. Platforms that connect manufacturers all over the world help keep printing local.

3. Recycling: You can 3D print things using recycled materials ranging from sawdust to coffee scraps.

4. Optimised parts: Printed parts can make aircraft or vehicles lighter, stronger and more aerodynamic. That means better fuel efficiency.

5. Extended end-of-life: Being able to print replacement parts, or spares, can make appliances, machines or vehicles last longer. You can even bring classics back to life by reverse engineering parts.

You're reading a brand new digital publication from the team at Professional Engineering, made exclusively for IMechE members and available on all devices. We'd love your feedback: let us know what you think at profeng@thinkpublishing.co.uk