The Rise of Offshore Hydrogen

Next winter, the UK will produce its first kilogram of offshore hydrogen. It’s far from alone in a race to prove that creating clean fuel out at sea makes economic sense. Alex Eliseev explores the global rise of offshore hydrogen – a new weapon in the fight against global warming.

To succeed, offshore hydrogen companies must produce an element that doesn’t appear on the periodic table: confidence.

To drive down the cost of turning water into fuel, 100km or more from shore, requires economies of scale. And that means huge investment, a solid supply chain, the right government policies and plenty of engineering skills.

The UK’s Dolphyn Hydrogen is one of a handful of global players racing towards a full-scale demonstrator – the key to harnessing industry confidence. In November, it plans to take a big step towards that goal by starting a round of tests off the west coast of Wales.

“This will be the first time that hydrogen is generated offshore in the UK,” explains Stephen Matthews, Dolphyn Hydrogen’s CEO. “It’s a big event. We’ve gone beyond the point of ‘will it work?’. That’s behind us. Now it’s down to how brave we can be.”

The offshore hydrogen tide is rising

Spin the globe and you’ll find nations taking brave steps towards mass-producing offshore hydrogen. Earlier this year, the Dutch government announced plans to build a large 500MW offshore hydrogen facility in the North Sea. In June, the French Sealhyfe project began producing small amounts of offshore hydrogen – which was claimed to be the world’s first. The UK government recently consulted industry on what its offshore hydrogen pipeline and storage policy should be. It’s also supporting an offshore hydrogen project in Scotland, which hopes to start production by 2025.

Under pressure to reduce carbon emissions, countries are embracing hydrogen as a key ingredient in their energy mix. America has its Hydrogen Shot plans, Japan’s just revised its hydrogen strategy (it plans to invest more than $100bn into hydrogen over the next 15 years) and China is ramping up its hydrogen targets.

What’s different about offshore hydrogen is that it offers the promise of green hydrogen – the cleanest there is – at scale.

The idea is straightforward. Take a wind (or wave) farm. Use the electricity it creates to power the hydrogen production, which involves purifying water and splitting hydrogen from oxygen using electrolysers. Then pipe the hydrogen back to shore, where it can be used or stored. There are different designs and configurations (using an electrolyser at each wind turbine or one per cluster of turbines, for instance) but the core idea is to tap into an abundant supply of renewable energy and water to make a fuel that leaves nothing but water vapour behind.

Catching up with the wind industry

Dolphyn Hydrogen has been working on its system design for five years. It’s applied for a global patent to protect the unique system it will rely on to produce and bring hydrogen back from floating farms.

The trial expected to kick off in Milford Haven, in Wales, will test a crucial component of this system: the electrolyser. There won’t be a wind turbine – not yet – but producing hydrogen on a barge will give the company a dress rehearsal. It will also allow it to run marine motion studies and see how the desalination process performs. The barge will start close to shore and, over several months, will be pushed further out.

Matthews has high expectations for the electrolysers that have been chosen, which he says are already used on nuclear submarines.

By 2026, the company plans to build a full-scale demonstrator, with a 10MW turbine the size of London’s Gherkin skyscraper.

“After that, we’ll move to our stepping-stone projects,” explains Matthews. “We want to build as many as three facilities that can power towns or small cities. We’ll start in the UK and then expand globally. In a decade, we’ll be where the wind industry is today, at full scale, talking in gigawatts.”

“With this technology, we’ll produce green hydrogen at the same cost as natural gas, Offshore hydrogen is more economic than most people believe, if you can get to scale quickly.”

A head start and big prizes at the finish

Matthews has worked in energy for more than a quarter of a century and is a partner at ERM, a global environmental consultancy that’s played a key role in setting up Dolphyn Hydrogen. He argues that sending hydrogen back to shore, along pipes, is more cost effective than getting electricity back to land. There’s no loss along the way, you need relatively low pressure and excess hydrogen can be stored in tanks or wider pipes, not expensive batteries. Plus you’re making the most of strong winds.

“With this technology, we’ll produce green hydrogen at the same cost as natural gas,” says Matthews. “Offshore hydrogen is more economic than most people believe, if you can get to scale quickly.”

Plus, he adds, it means producers don’t get tangled up with grid connections, which can slow down ambitious projects and lead to missed decarbonisation targets.

There are other advantages to offshore hydrogen. Amey Karnik, head of industrial decarbonisation at Ramboll, an engineering-focused consultancy, says he expects to see more pilot projects pave the way for serious offshore hydrogen growth.

Karnik, a chartered mechanical engineer and member of the Institution of Mechanical Engineers (IMechE), says that, given how much water it takes to produce hydrogen, it makes sense to do it at sea. Old oil and gas pipelines can be repurposed and there are export opportunities for those who get it right. Karnik agrees that the costs can be pushed down if mass production takes off, and as renewable energy gets cheaper.

“The most important thing is to understand where offshore hydrogen solutions fit the best, and not to force them where they don’t make sense,” he explains. “Go for low hanging fruit. Tap into existing demand from heavy industry, chemicals, transport, shipping and aviation. Hydrogen helps industries that find it difficult to decarbonise.”

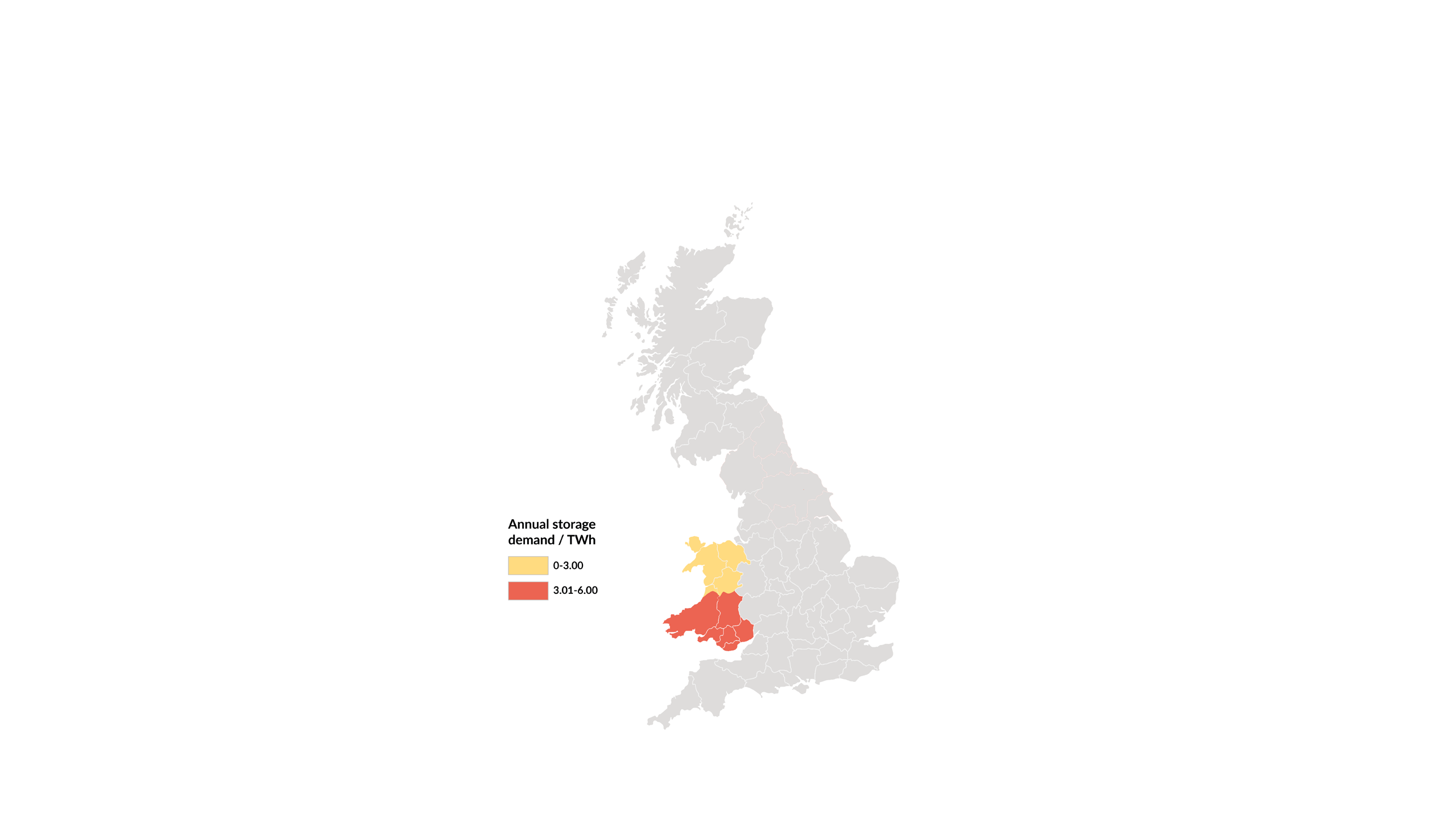

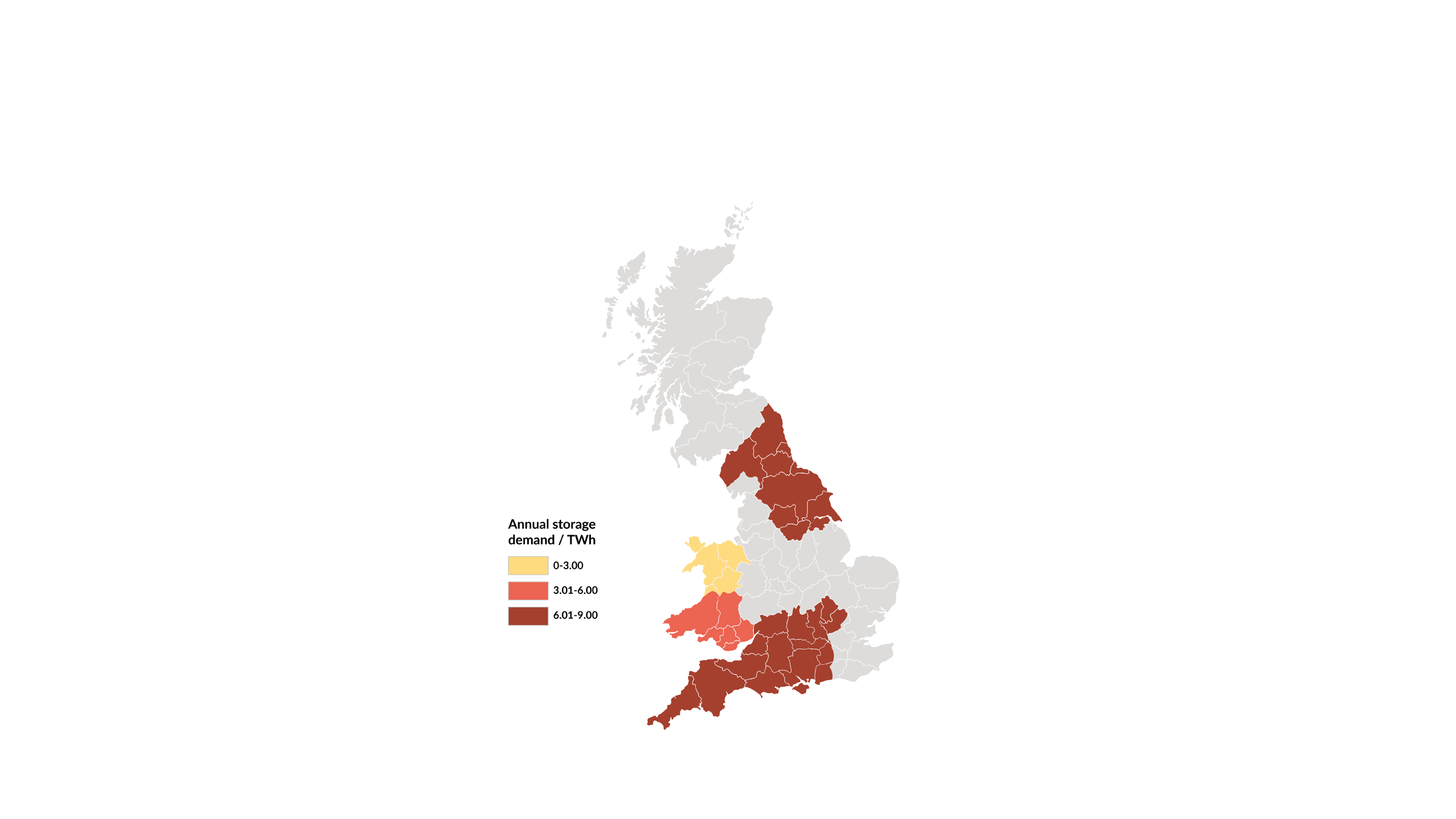

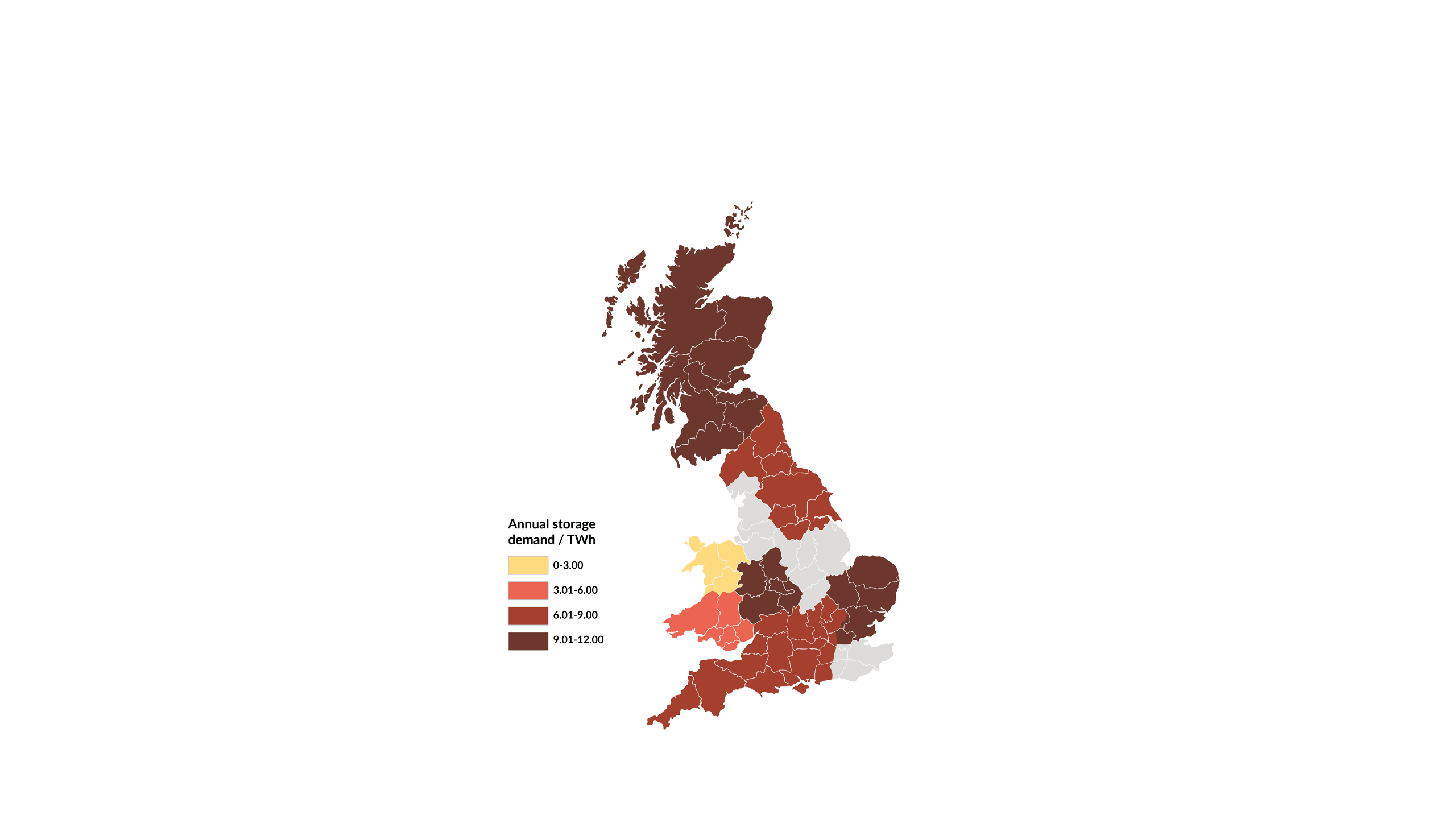

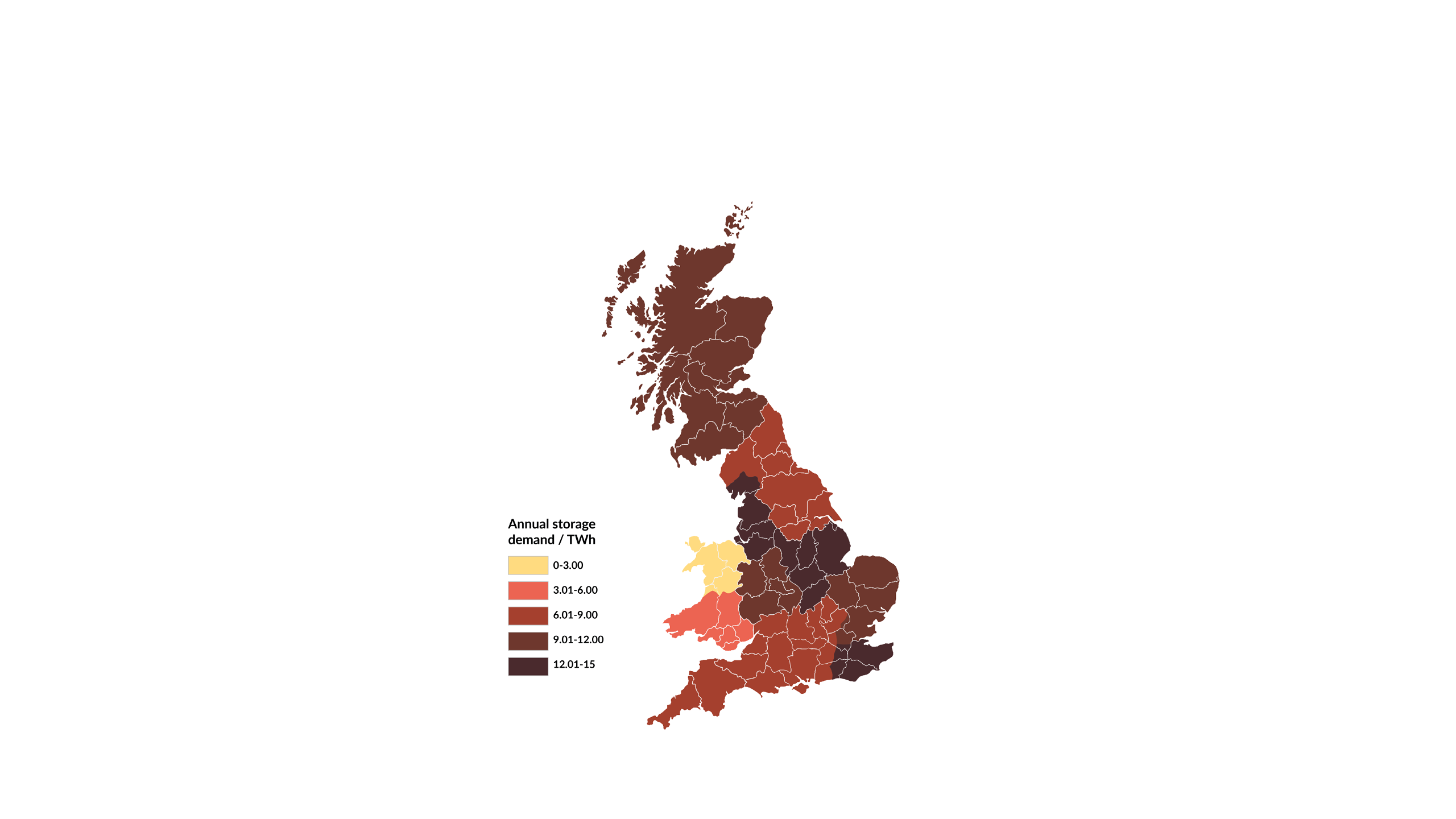

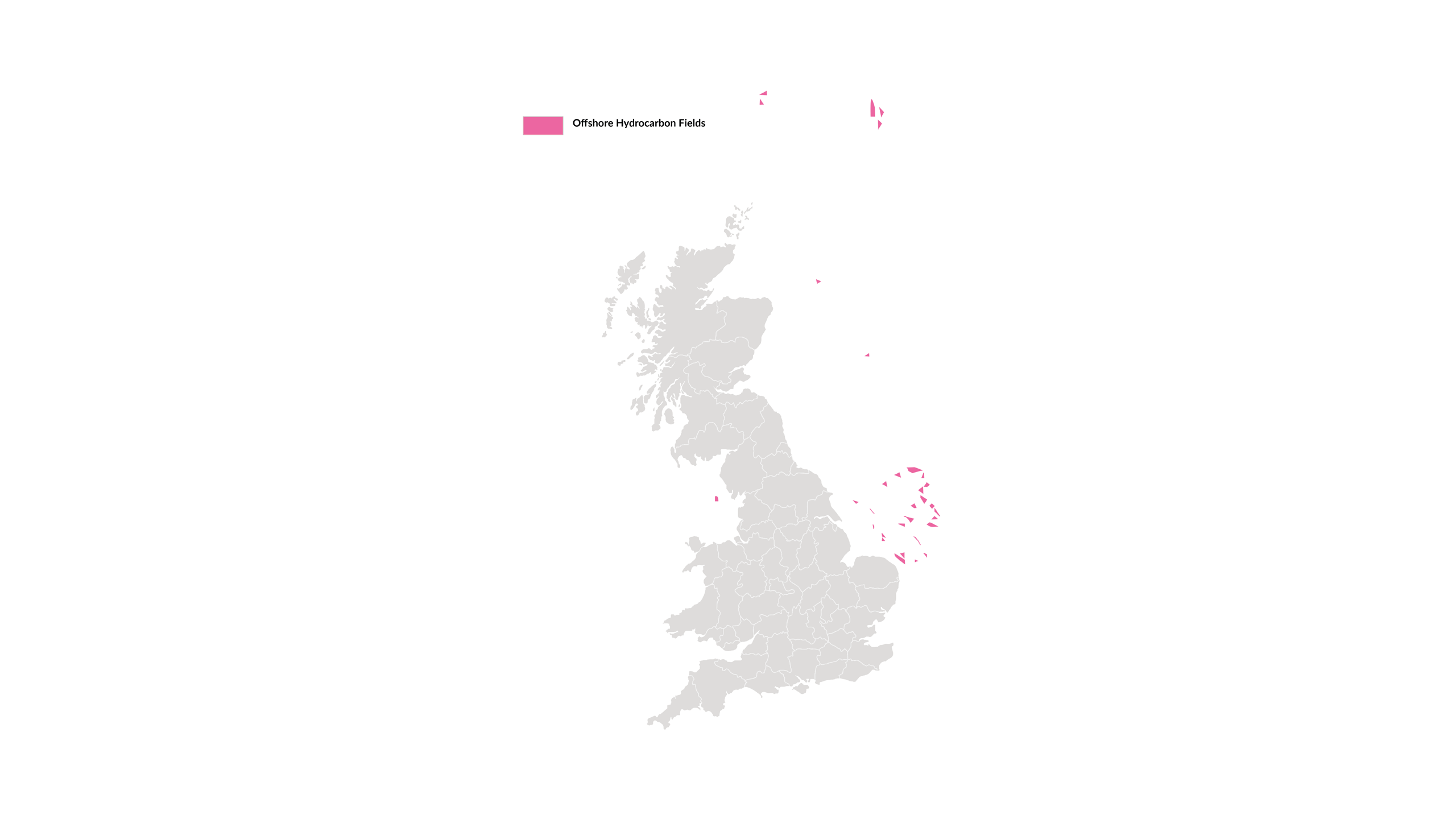

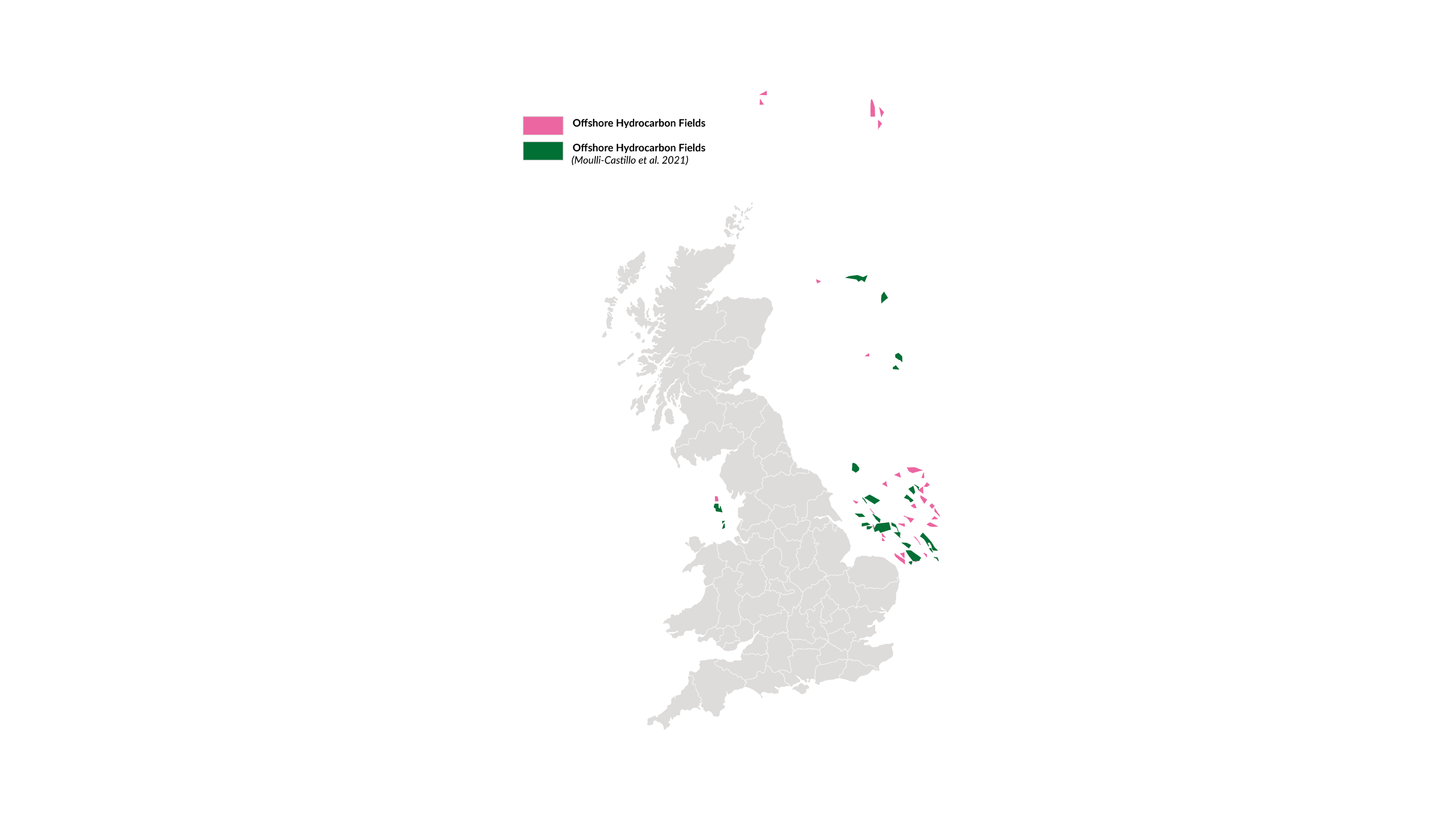

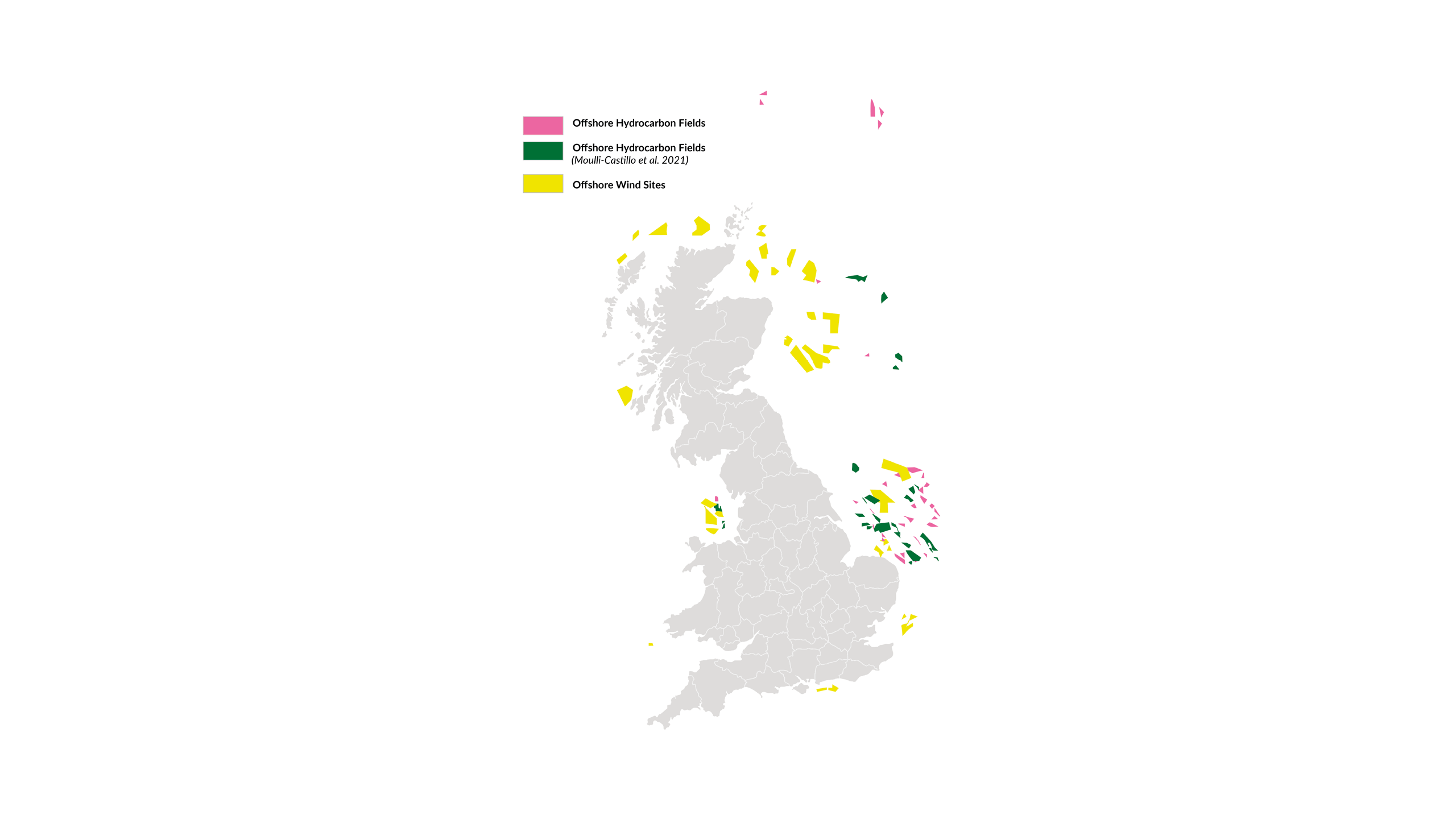

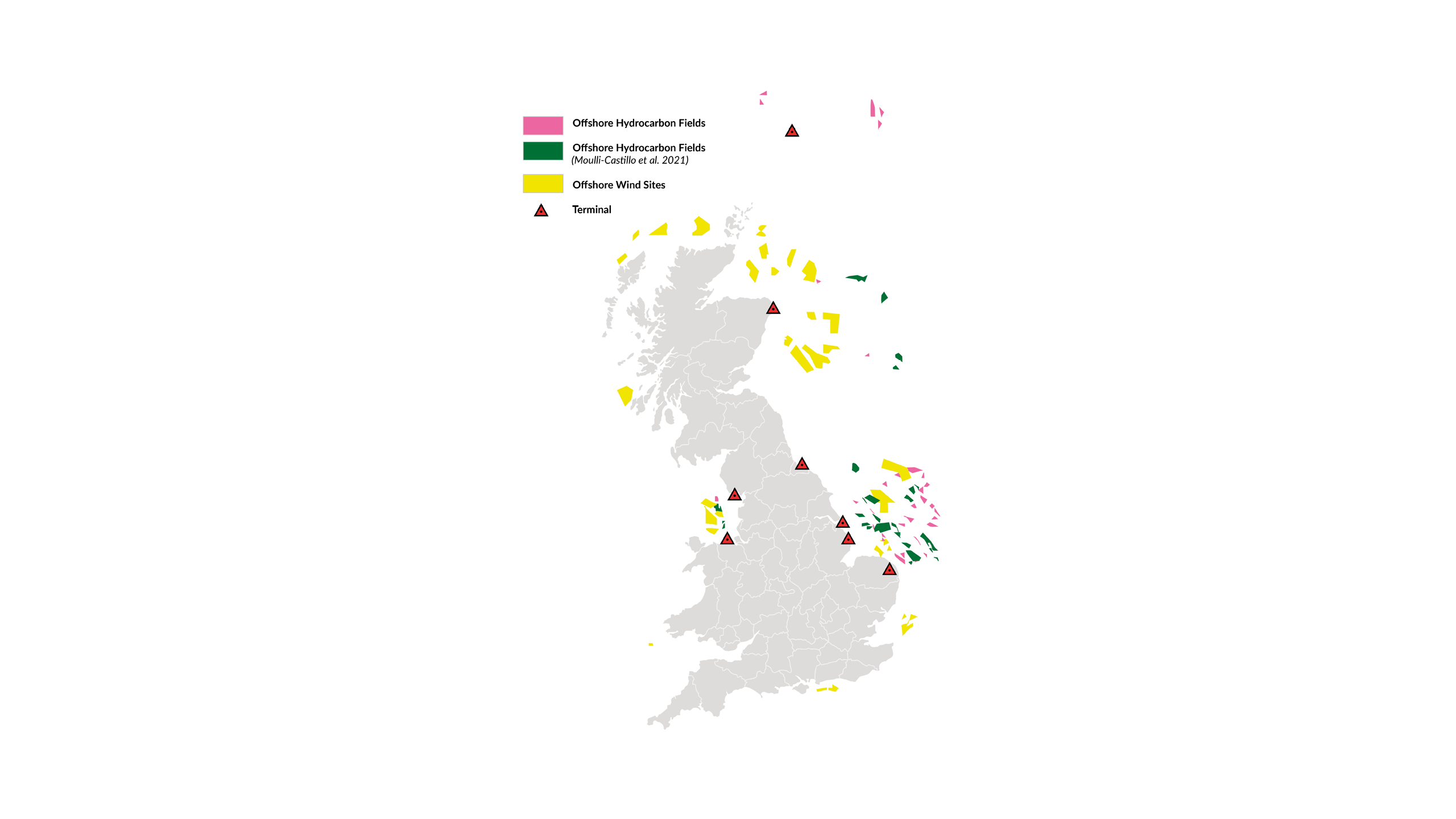

Mapping hydrogen storage capacities of UK offshore hydrocarbon fields and exploring potential synergies with offshore wind

As well as creating energy to turn into hydrogen, the North Sea’s hydrocarbon fields offer an opportunity for that hydrogen to be stored, as demonstrated by this map showing the location of offshore wind farms in relation to oil and gas fields.

data by Peecock et al.

It’s not all smooth sailing

Karnik, and other experts, say there are challenges that must be dealt with before offshore hydrogen hits its commercial breakthrough. Safety, for one, has always been a part of the hydrogen story. Going offshore presents new problems.

Building, fixing or maintaining structures on rough seas can be more expensive, Karnik explains. Pumping hydrogen through underwater pipes raises concerns about ecological impacts. There are unanswered questions about excess heat and oxygen created at hydrogen plants (it’s easier to find a use for those back on land). And there are concerns about whether electrolyser technology can develop fast enough to service a booming offshore hydrogen sector – with questions around how long the machines can last and how new designs will adapt to life at sea.

“Every sector you can think of has the potential to use hydrogen. The sooner we get green hydrogen production, the better. It’s important to get it done, and produce it in large quantities. Otherwise, we won’t meet our 2030 targets.”

One person anxiously waiting for answers is Professor Mohamed Pourkashanian, who heads the Energy Institute at the University of Sheffield. With 40 years of energy research under his belt, and an OBE for his contribution to the field, Pourkashanian jokes that his top three concerns are: price, price and price.

Cost of production, he says, remains a major hurdle. Others include clear government policies and electrolyser technology challenges.

“I’m looking forward to full lifecycle analyses,” says Pourkashanian. “Comparing technologies will tell us more about costs, practicality and the robustness of offshore hydrogen.”

Pourkashanian says he’s particularly interested to see how offshore compares to onshore production, and to local hydrogen facilities that could use small modular reactor (SMR) nuclear power instead of wind.

“Every sector you can think of has the potential to use hydrogen. The sooner we get green hydrogen production, the better. It’s important to get it done, and produce it in large quantities. Otherwise, we won’t meet our 2030 targets.”

Licence to fill (the pipelines)

Matthews agrees, saying it’s important to put different technologies to the test and settle on those that deliver the best results. Failing to do that would be the equivalent of trying to mass-produce cars with hundreds of different engine types.

As Matthews sees it, the tallest hurdle is securing space to run demonstrator projects and stepping-stone facilities.

Offshore licences, he says, are crucial to building confidence and applying a stepped approach to learning and refining. In other words, they’ll give the industry the analysis and comparisons it needs. But competing in large licensing rounds can push projects beyond 2030, so Dolphyn is looking for partners and sites where existing licences can be modified to accommodate offshore hydrogen initiatives.

“One of the most rewarding things for us is to work on a solution that’s fit for our future. This industry is going to show something like a 40% compound annual growth rate,” says Matthews. “It’s innovative. It’s new. And my message is: don’t wait and watch. Get engaged, build up investment and plan to make a move.”

For engineers, endless puzzles to solve

While, like any new technology, offshore hydrogen has its sceptics, what everyone agrees on is that it offers exciting opportunities for engineers.

Matthews says that, as an adjacent industry – as opposed to an entirely new one – offshore hydrogen offers a chance for engineers to transition, relatively easily, from sectors such as oil and gas, construction or steel fabrication. Dolphyn Hydrogen has hundreds of companies in its supply chain and, Matthews adds, once construction begins at scale, thousands of jobs will be created.

Karnik says offshore hydrogen serves up endless puzzles – from solving pressure fluctuations to designing the most effective pipelines. Not to mention designing the kind of infrastructure that can withstand gale-force winds and pounding waves.

Hydrogen Europe, an association representing the industry, says engineers will play a key role in complex projects and can use their talents to bring down production costs.

“If we can crack the economics, it could be the single most important method of green hydrogen production in Europe, with its vast amounts of capacity around our western and north-western shores,” says Daniel Fraile, the association’s chief policy officer. “First movers will pave the way for widespread uptake of offshore hydrogen production.”

An invisible gas with plenty of colours:

There’s green hydrogen, blue hydrogen and even turquoise hydrogen. There’s grey, black and pink hydrogen. That’s a whole lot of colours for an invisible gas.

There are many ways to produce hydrogen. These colour labels help us understand how clean each method is. Ramboll, where Karnik works, has a handy guide to help you understand the hydrogen rainbow.

Green hydrogen: the sustainable, carbon-free hydrogen

Let’s start with the ‘green’ end of the colour spectrum. Green hydrogen is the term used for hydrogen that is made by means of electrolysis using renewable energy sources, such as wind, solar or hydro power. Electrolysers use an electrochemical reaction to split water into its components of hydrogen and oxygen – emitting zero greenhouse-gas emissions in the process. Green hydrogen is the clean alternative to fossil fuels and has tremendous potential as a critical enabler in the global transition towards a sustainable energy economy.

Blue hydrogen: the low-carbon hydrogen

Blue hydrogen is made from fossil fuels, typically natural gas, by using steam-methane-reforming or auto-thermal-reforming processes. The output is H2 but also carbon dioxide as a by-product. By capturing the CO2 at the source and storing it underground, blue hydrogen can become a low-carbon product. This is also referred to as carbon sequestration.

Grey hydrogen: the traditional process

Grey hydrogen is considered the ‘traditional’ method of producing H2 and is currently the most common form of hydrogen production. Using a steam reforming process, grey hydrogen is produced from natural gas, but without capturing the carbon dioxide in the process.

Black (or brown) hydrogen: coal

At the very opposite end of the spectrum from green hydrogen is black hydrogen made from fossil fuels. Hydrogen is produced from black coal or lignite (brown coal) through a ‘gasification’ process.

Pink hydrogen: nuclear energy

Pink hydrogen also finds its place in the colour spectrum. Pink hydrogen refers to H2 which is produced through electrolysis powered by nuclear energy. In some cases, this production form is also referred to as purple or red hydrogen.

Turquoise hydrogen: methane pyrolysis

Finally, a recent addition to the spectrum is turquoise hydrogen. Turquoise hydrogen is made using methane pyrolysis, which splits methane into hydrogen gas and solid carbon. This is still very immature and unlikely to play a big role. In the future, turquoise hydrogen might be considered as a low-emissions choice depending on the process being powered by renewable energy and whether the carbon will be permanently stored or used.