ENGINEERING IN

2025

We asked leaders from across engineering to share their predictions for the industry in 2025. Their answers take in everything from additive manufacturing to artificial intelligence – and offer a sharp insight into what engineers can expect in the next 12 months

ENGINEERING

IN 2025

We asked leaders from across engineering to share their predictions for the industry in 2025. Their answers take in everything from additive manufacturing to artificial intelligence – and offer a sharp insight into what engineers can expect in the next 12 months

01

Countries will scramble to build their own batteries

China currently supplies over 90% of the world’s cathode active materials used to make Lithium-ion cells: these materials are critical because they determine the battery’s overall performance and durability.

Should China decide to restrict exports in retaliation for increased tariffs it would severely affect the West’s ability to manufacture EVs. That’s why we set up the UK’s only pilot plant making cathode active materials for Lithium Iron Phosphate and Lithium Manganese Iron Phosphate cells, using raw materials sourced from Europe and North America.

Legislation is also encouraging the strengthening of supply chains and reducing reliance on China: the US Inflation Reduction Act and UK-EU Rules of Origin regulations require an increasing percentage of the battery’s value to be sourced locally. E-mobility is fundamental to achieving net zero, so I expect 2025 to bring renewed focus on building up domestic battery supply chains, for which government funding is urgently needed.

Behnam Hormozi, founder and CEO, Integrals Power

01

Countries will scramble to build their own batteries

China currently supplies over 90% of the world’s cathode active materials used to make Lithium-ion cells: these materials are critical because they determine the battery’s overall performance and durability.

Should China decide to restrict exports in retaliation for increased tariffs it would severely affect the West’s ability to manufacture EVs. That’s why we set up the UK’s only pilot plant making cathode active materials for Lithium Iron Phosphate and Lithium Manganese Iron Phosphate cells, using raw materials sourced from Europe and North America.

Legislation is also encouraging the strengthening of supply chains and reducing reliance on China: the US Inflation Reduction Act and UK-EU Rules of Origin regulations require an increasing percentage of the battery’s value to be sourced locally. E-mobility is fundamental to achieving net zero, so I expect 2025 to bring renewed focus on building up domestic battery supply chains, for which government funding is urgently needed.

Behnam Hormozi, founder and CEO, Integrals Power

02

Engineers will focus on optimising power use

Engineering in 2025 will be defined by innovations that enhance energy efficiency and manage power quality. We’re already seeing advances in Class A meters that measure supraharmonics – an area of the frequency spectrum that is overlooked by traditional meters. As the integration of electric vehicles, renewable energy and other complex systems grows, precise power quality monitoring will be needed to prevent disturbances that could disrupt sensitive equipment and grid stability. Beyond monitoring, regenerative braking – or regen – technology will be a game-changer in applications like elevators, where efficient energy use is increasingly a priority. By capturing and reusing excess energy, rather than dissipating it as heat, regen solutions offer a significant step towards reducing waste and managing energy loads sustainably.

John Mitchell, global sales and marketing director at CP Automation

03

Decarbonisation discussions will turn towards heavy industry

Momentum towards decarbonisation, particularly electricity, has been rapidly growing in recent years. Many low-carbon technologies, like electric vehicles and wind and solar power, are almost competitive without subsidy, reaching a tipping point beyond which they will become the default choices. Policy focus is turning to enabling technologies in the power sector, like storage, and to parts of the energy system that are hard to decarbonise.

For heavy industry decarbonisation, international negotiations will ramp up over the implementation of carbon border adjustment mechanisms (CBAMs). The EU has already passed CBAM legislation, and the UK has promised to do so by 2027. The idea is that products are taxed on their embedded emissions, so that countries that decarbonise faster are not penalised by an exodus of engineering companies seeking laxer environmental levies. However, many developing nations will push back as they claim these are protectionist tariffs implemented by the backdoor, and may not be WTO compliant.

More broadly, net zero and the other grand challenges faced by humanity will require a rapid growth in the engineering talent pipeline and widescale reskilling. This is why, in the UK, IMechE is calling for a National Engineering and Technology Workforce Strategy to address the shortfall.

Matt Rooney, IMechE head of policy

03

Decarbonisation discussions will turn towards heavy industry

Momentum towards decarbonisation, particularly electricity, has been rapidly growing in recent years. Many low-carbon technologies, like electric vehicles and wind and solar power, are almost competitive without subsidy, reaching a tipping point beyond which they will become the default choices. Policy focus is turning to enabling technologies in the power sector, like storage, and to parts of the energy system that are hard to decarbonise.

For heavy industry decarbonisation, international negotiations will ramp up over the implementation of carbon border adjustment mechanisms (CBAMs). The EU has already passed CBAM legislation, and the UK has promised to do so by 2027. The idea is that products are taxed on their embedded emissions, so that countries that decarbonise faster are not penalised by an exodus of engineering companies seeking laxer environmental levies. However, many developing nations will push back as they claim these are protectionist tariffs implemented by the backdoor, and may not be WTO compliant.

More broadly, net zero and the other grand challenges faced by humanity will require a rapid growth in the engineering talent pipeline and widescale reskilling. This is why, in the UK, IMechE is calling for a National Engineering and Technology Workforce Strategy to address the shortfall.

Matt Rooney, IMechE head of policy

04

Smart policymakers will unlock funding for carbon capture

The right mix of supportive policies, financial mechanisms, and technological innovation can de-risk investments in carbon capture, utilisation and storage (CCUS) and maximise the potential for green investment amid uncertain times, while also addressing the role of oil and gas in the transition. CCUS has the scope to play a pivotal role in the latter sectors. It can be readily deployed at fossil fuel power plants and industrial facilities, such as cement, iron and steel, and chemicals, where CO2 is captured and stored or used to create products such as fuels and chemicals (CCU).

Mobilising the capital needed to achieve the ambitious targets will require careful design of policies, financing mechanisms and incentives, and innovation funding. These measures must work together to de-risk investments, boost capital availability, and ultimately make clean energy technologies economically sustainable. The oil and gas industry has a critical role to play in this transition, by leveraging its expertise, infrastructure, and financial resources to support the deployment of CCUS and other low-carbon technologies.

The path to a sustainable energy future is complex and challenging, but it is also filled with opportunity. By harnessing the power of policy, technology, and finance, we can unlock the vast potential of green investment and accelerate the transition to a low-carbon economy.

Dr Valentina Dedi, lead economist at KBR

04

Smart policymakers will unlock funding for carbon capture

The right mix of supportive policies, financial mechanisms, and technological innovation can de-risk investments in carbon capture, utilisation and storage (CCUS) and maximise the potential for green investment amid uncertain times, while also addressing the role of oil and gas in the transition. CCUS has the scope to play a pivotal role in the latter sectors. It can be readily deployed at fossil fuel power plants and industrial facilities, such as cement, iron and steel, and chemicals, where CO2 is captured and stored or used to create products such as fuels and chemicals (CCU).

Mobilising the capital needed to achieve the ambitious targets will require careful design of policies, financing mechanisms & incentives, and innovation funding. These measures must work together to de-risk investments, boost capital availability, and ultimately make clean energy technologies economically sustainable. The oil and gas industry has a critical role to play in this transition, by leveraging its expertise, infrastructure, and financial resources to support the deployment of CCUS and other low-carbon technologies.

The path to a sustainable energy future is complex and challenging, but it is also filled with opportunity. By harnessing the power of policy, technology, and finance, we can unlock the vast potential of green investment and accelerate the transition to a low-carbon economy.

Dr Valentina Dedi, lead economist at KBR

05

Commercial EV charging will create new bottlenecks

As electric commercial-vehicle uptake increases through next year, energy demand at fleet charging depots will create significant challenges. It will broaden peak-price charging times, but also present huge capex hurdles. Over 50% of depots face grid constraints, and many fleets are unwilling to pour capital investment into upgrading them – especially as many aren’t even owned by the fleets.

Agile infrastructure is the key to plugging grid gaps. High-performance powerbanks and smart charging technology mean fleets can draw power from the grid when most cost-efficient, and store it for an intensive DC boost-charge. These technologies are needed to keep vehicles running efficiently and on-time, and provide DC charging in locations that otherwise couldn’t.

These solutions will play a crucial role in maximising fleet uptime and off-grid flexibility, when they may not be able to rely on capacity at off-site hubs – all of which is critical for facilitating cost-effective electrification.

Philip Clarke, CEO and founder of TUAL

06

Electric hydrofoils will conquer the seas

The largest challenge in achieving true sustainability in maritime transport lies in significantly enhancing the performance of electric vessels to meet the diverse demands of marine applications worldwide. Fortunately, electric hydrofoiling technology is a major step forward – increasing the range and efficiency of electric vessels while also providing a smoother, more comfortable ride.

In 2025, electric hydrofoiling is set to enter a new phase of adoption. Currently, there are fewer than 200 electric hydrofoiling vessels in operation, with only a select few certified for commercial passenger use, such as the Vessev VS-9. This is in contrast to the 33 million vessels in existence worldwide. The year 2025 marks the beginning of this great transition, with electric hydrofoiling leading the way. There is no shortage of reasons to be optimistic about a genuinely sustainable future.

Erik Laakmann, CEO of Vessev

06

Electric hydrofoils will conquer the seas

The largest challenge in achieving true sustainability in maritime transport lies in significantly enhancing the performance of electric vessels to meet the diverse demands of marine applications worldwide. Fortunately, electric hydrofoiling technology is a major step forward – increasing the range and efficiency of electric vessels while also providing a smoother, more comfortable ride.

In 2025, electric hydrofoiling is set to enter a new phase of adoption. Currently, there are fewer than 200 electric hydrofoiling vessels in operation, with only a select few certified for commercial passenger use, such as the Vessev VS-9. This is in contrast to the 33 million vessels in existence worldwide. The year 2025 marks the beginning of this great transition, with electric hydrofoiling leading the way. There is no shortage of reasons to be optimistic about a genuinely sustainable future.

Erik Laakmann, CEO of Vessev

07

AI will accelerate engineering design

Accelerating the clean energy transition hinges on overcoming fundamental engineering bottlenecks to the deployment of more efficient technologies and machines at scale. From time-consuming physics simulation to the painstaking reconciliation of virtual simulation and real-world data collection, there are many bottlenecks holding back industries from developing and manufacturing advanced designs and materials.

We therefore expect a new class of AI-first digital engineering solutions to be a major growth opportunity in 2025. These AI models will dramatically accelerate accurate physics simulation, enable generative engineering, and accelerate some of the most time-consuming activities in the engineering process – making complex engineering across industries more accessible.

Engineering design processes were transformed by numerical simulation and the availability of high-performance compute infrastructure. The move from numerical simulation to deep learning represents a similar leap.

Jacomo Corbo, co-founder & CEO of PhysicsX

07

AI will accelerate engineering design

Accelerating the clean energy transition hinges on overcoming fundamental engineering bottlenecks to the deployment of more efficient technologies and machines at scale. From time-consuming physics simulation to the painstaking reconciliation of virtual simulation and real-world data collection, there are many bottlenecks holding back industries from developing and manufacturing advanced designs and materials.

We therefore expect a new class of AI-first digital engineering solutions to be a major growth opportunity in 2025. These AI models will dramatically accelerate accurate physics simulation, enable generative engineering, and accelerate some of the most time-consuming activities in the engineering process – making complex engineering across industries more accessible.

Engineering design processes were transformed by numerical simulation and the availability of high-performance compute infrastructure. The move from numerical simulation to deep learning represents a similar leap.

Jacomo Corbo, co-founder & CEO of PhysicsX

08

AI will supercharge the race for better batteries

We're going to see battery test labs using AI a lot more in 2025. They're producing terabytes of data per week on chemical composition and design, validation and ageing testing, manufacturing processes and field monitoring. Machine learning is the only approach capable of analysing these huge data sets in a timely manner.

For example, in the race to build better batteries, engineers must find designs that are not only high performing, but also manufacturable in the most profitable model. At the same time they need to reduce time to market without risking product safety or brand reputation.

An AI-driven 'high throughput lab' can address these challenges by using test data to identify better designs, optimise test plans, and accelerate the innovation process with fewer, more productive prototypes.

Smaller, more nimble startups are already leveraging AI to accelerate their design, testing, and manufacturing processes. We expect the bigger OEMs to come on board as they see how incorporating AI tools into their labs results in better, faster engineering processes and better-performing batteries.

Richard Ahlfeld, founder & CEO of Monolith

09

AI and VR will reshape teaching

From the curriculum and assessment review, formation of Skills England and the industrial strategy call for evidence, I believe 2025 will be a time where we will see clear directions for a lot of these big plans from Labour.

Rapid advancements in AI and virtual reality (VR) are expected to reshape teaching and learning methods. Virtual labs and simulations will likely replace traditional setups, offering students realistic and cost-effective environments to experiment with engineering principles. AI-driven adaptive learning platforms will offer personalised educational paths, identifying individual strengths and weaknesses and tailoring content to optimise learning outcomes.

We hope to see more interdisciplinary education – for example, students could collaborate on projects addressing climate change, combining skills from environmental engineering, computer modelling, and policy analysis.

Curricula will increasingly emphasise sustainability and ethics, preparing engineers to tackle global challenges like climate change and resource scarcity. Accredited programmes will be assessed on how sustainability is embedded into their learning, and tools like the Reimagined Degree Map will bring sustainability into focus.

Collaboration between academia and industry will intensify, ensuring engineering education remains aligned with workforce demands and helping upskill engineers already in the workforce.

We expect engineers to be leaders, innovators and role models in addressing the complex challenges of the future, so in 2025 we will provide more guidance on adaptability, ethical responsibility and interdisciplinary collaboration.

Lydia Amarquaye, IMechE education & skills policy lead

09

AI and VR will reshape teaching

From the curriculum and assessment review, formation of Skills England and the industrial strategy call for evidence, I believe 2025 will be a time where we will see clear directions for a lot of these big plans from Labour.

Rapid advancements in AI and virtual reality (VR) are expected to reshape teaching and learning methods. Virtual labs and simulations will likely replace traditional setups, offering students realistic and cost-effective environments to experiment with engineering principles. AI-driven adaptive learning platforms will offer personalised educational paths, identifying individual strengths and weaknesses and tailoring content to optimise learning outcomes.

We hope to see more interdisciplinary education – for example, students could collaborate on projects addressing climate change, combining skills from environmental engineering, computer modelling, and policy analysis.

Curricula will increasingly emphasise sustainability and ethics, preparing engineers to tackle global challenges like climate change and resource scarcity. Accredited programmes will be assessed on how sustainability is embedded into their learning, and tools like the Reimagined Degree Map will bring sustainability into focus.

Collaboration between academia and industry will intensify, ensuring engineering education remains aligned with workforce demands and helping upskill engineers already in the workforce.

We expect engineers to be leaders, innovators and role models in addressing the complex challenges of the future, so in 2025 we will provide more guidance on adaptability, ethical responsibility and interdisciplinary collaboration.

Lydia Amarquaye, IMechE education & skills policy lead

10

Industrial AI will transform how engineers access knowledge

Automation and artificial intelligence will drive significant changes in the engineering sector in 2025. Engineers are aiming to reduce the time spent looking for and checking information. Breaking down traditional silos will enable more effective sharing of technical engineering data across cloud and hybrid environments. To ensure this, engineers will need to implement changes that unify information and data management across the entire design and operational lifecycle.

Industrial artificial intelligence, incorporated into tools and tested in customers’ workflows, will help to deliver projects faster with less margin for error. AI’s ability to analyse complex and extensive datasets, across different products, will help engineers arrive at informed decisions rapidly, automate operational tasks and streamline workflows. Relationships between owner-operators and their EPCs are key to the success of capital projects in the engineering industry. Current practices regarding collaboration between organisations, as well as internally within organisations, often lead to project inefficiencies. The next wave of professionals entering the workforce expect greater, more data-centric, real-time collaboration. Technology that enables the digital twin and that effectively harnesses artificial intelligence will be at the forefront of driving the necessary industry transformation.

Jon Hobbs, R&D SVP, engineering business at AVEVA

10

Industrial AI will transform how engineers access knowledge

Automation and artificial intelligence will drive significant changes in the engineering sector in 2025. Engineers are aiming to reduce the time spent looking for and checking information. Breaking down traditional silos will enable more effective sharing of technical engineering data across cloud and hybrid environments. To ensure this, engineers will need to implement changes that unify information and data management across the entire design and operational lifecycle.

Industrial artificial intelligence, incorporated into tools and tested in customers’ workflows, will help to deliver projects faster with less margin for error. AI’s ability to analyse complex and extensive datasets, across different products, will help engineers arrive at informed decisions rapidly, automate operational tasks and streamline workflows. Relationships between owner-operators and their EPCs are key to the success of capital projects in the engineering industry. Current practices regarding collaboration between organisations, as well as internally within organisations, often lead to project inefficiencies. The next wave of professionals entering the workforce expect greater, more data-centric, real-time collaboration. Technology that enables the digital twin and that effectively harnesses artificial intelligence will be at the forefront of driving the necessary industry transformation.

Jon Hobbs, R&D SVP, engineering business at AVEVA

11

There will be reasons for optimism despite new pressures on labour cost

Despite the ongoing challenges caused by Brexit, we do expect to increase our exports next year, particularly to France. We continue to win orders from our long-term rail customers as they overhaul their fleets of trains and our automotive customer base and work continues to grow, so there are certainly reasons for optimism. However, we must be mindful of the pressure on labour costs from recently announced government policy, not only from our five figure increase in employer’s National Insurance contributions, but also the significant increase in the national minimum wage for both 18-20's and over 21s, which will further narrow the gap with our more skilled workers.

Andy Pailor, managing director of precision engineering specialist, JJ Hardy & Sons Ltd

12

Customer support will get a long-needed upgrade

The digitalisation of the aftersales experience will be a major priority for manufacturers in 2025 as they look to improve end-user experiences. This will prove super helpful for engineers as it will bring together various forms of documentation such as maintenance manuals and parts catalogues on platforms that can incorporate instant ordering functionality.

Currently, engineers and technical documentation teams rely on a variety of PDFs and paper-based documentation. Not only do these documents quickly become outdated as new product versions are released, but the 2D format often makes instructions hard to follow and parts difficult to identify – never mind source and buy.

To make life easier for engineers, manufacturers are starting to take advantage of technology that will allow them to automatically convert their product CAD designs into 3D models. This is helping them to build customer service platforms that offer a highly visual, user-friendly and up-to-date parts catalogue that will assist in both the identification and ordering of parts directly from the OEM.

Sam Burgess, CEO, Partful

12

Customer support will get a long-needed upgrade

The digitalisation of the aftersales experience will be a major priority for manufacturers in 2025 as they look to improve end-user experiences. This will prove super helpful for engineers as it will bring together various forms of documentation such as maintenance manuals and parts catalogues – on platforms that can incorporate instant ordering functionality.

Currently, engineers and technical documentation teams rely on a variety of PDFs and paper-based documentation. Not only do these documents quickly become outdated as new product versions are released, but the 2D format often makes instructions hard to follow and parts difficult to identify – never mind source and buy.

To make life easier for engineers, manufacturers are starting to take advantage of technology that will allow them to automatically convert their product CAD designs into 3D models. This is helping them to build customer service platforms that offer a highly visual, user-friendly and up-to-date parts catalogue that will assist in both the identification and ordering of parts directly from the OEM.

Sam Burgess, CEO, Partful

13

Defence, nuclear and rail will benefit from new investment

In the aerospace sector, we’re seeing increased spending in defence, with world events acting as a catalyst for innovation. For example, we’re seeing innovative product development in sensor and laser technology, as well as unmanned air systems. At Morson Projects, we’re supporting the Tempest sixth generation fighter jet programme, along with both the Dreadnought and AUKUS next-generation submarines.

Meanwhile in the civil aviation industry, environmental drivers are spurring on innovation. The race to develop hydrogen powered aircraft continues and there’s also strong competition to be the first to launch an eVTOL (electric vehicle take off and landing) product, and make urban air mobility a reality. Power generation and distribution is another dynamic industry for engineering.

We’re seeing huge investment in renewables and nuclear, with four companies now pioneering Small Modular Reactor (SMR) products, including the Rolls-Royce SMR project we are supporting. This will need to be underpinned by the 'Great Grid Upgrade', which sees extensive development of our distribution network; ultimately we must respond to our growing demand for electricity.

With rail being one of the industries earmarked for investment in the budget, there will also be some exciting engineering projects ahead in this sector, including the Transpennine route upgrade and the HS2 connection to Euston.

There is so much going on, it really is a very exciting time for the sector!

Gareth Beck, divisional director - maritime, aerospace and defence at Morson Projects

13

Defence, nuclear and rail will benefit from new investment

In the aerospace sector, we’re seeing increased spending in defence, with world events acting as a catalyst for innovation. For example, we’re seeing innovative product development in sensor and laser technology, as well as unmanned air systems. At Morson Projects, we’re supporting the Tempest sixth generation fighter jet programme, along with both the Dreadnought and AUKUS next generation submarines.

Meanwhile in the civil aviation industry, environmental drivers are spurring on innovation. The race to develop hydrogen powered aircraft continues and there’s also strong competition to be the first to launch an eVTOL (electric vehicle take off and landing) product, and make urban air mobility a reality. Power generation and distribution is another dynamic industry for engineering.

We’re seeing huge investment in renewables and nuclear, with four companies now pioneering Small Modular Reactor (SMR) products, including the Rolls-Royce SMR project we are supporting. This will need to be underpinned by the 'Great Grid Upgrade', which sees extensive development of our distribution network; ultimately we must respond to our growing demand for electricity.

With rail being one of the industries earmarked for investment in the budget, there will also be some exciting engineering projects ahead in this sector, including the Transpennine route upgrade and the HS2 connection to Euston.

There is so much going on, it really is a very exciting time for the sector!

Gareth Beck, divisional director - maritime, aerospace and defence at Morson Projects

14

Sustainability and skills will continue to impact manufacturing

As we move into 2025, the push for sustainability will continue to have a big impact on manufacturing. While companies have been already looking at how they can make their processes more environmentally friendly, I think there will be a greater desire from customers and clients to see eco-friendly products, as everyone works towards net-zero targets.

Alongside this, having a skilled, reliable workforce is key for manufacturers going forward. Recruiting skilled workers has proven to be difficult over the past few years, but as an industry, I think it’s important we encourage young people to get into engineering roles, whether that’s through apprenticeships, or speaking to schools and colleges.

It’s also traditionally been difficult to recruit women in engineering roles, and again we should be working to make the industry more appealing to a diverse range of people.

The integration of digital technologies into engineering, with the rise of AI and automation over recent years, means that young workers coming into the industry need to be multi-skilled and learn how to become prompt engineering experts, which will only benefit everyone going forward.

Andy Turner, sales & operations manager at SEW-EURODRIVE UK

15

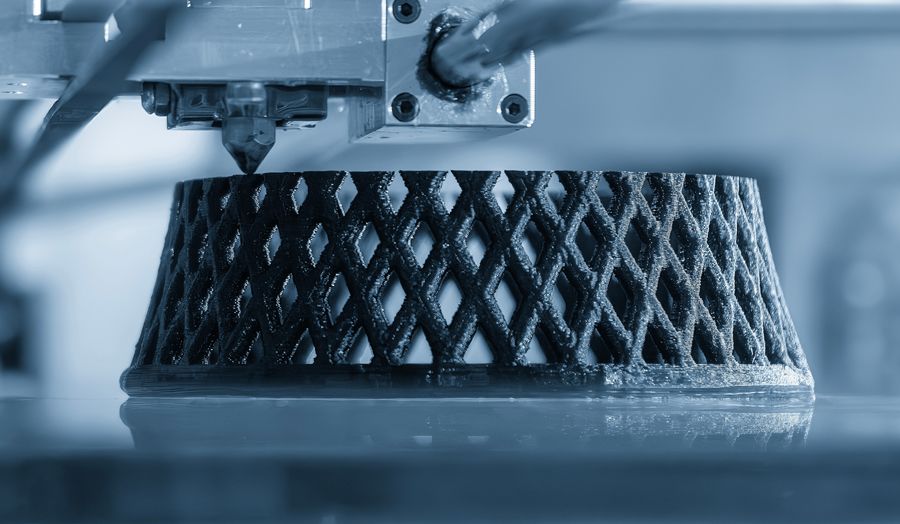

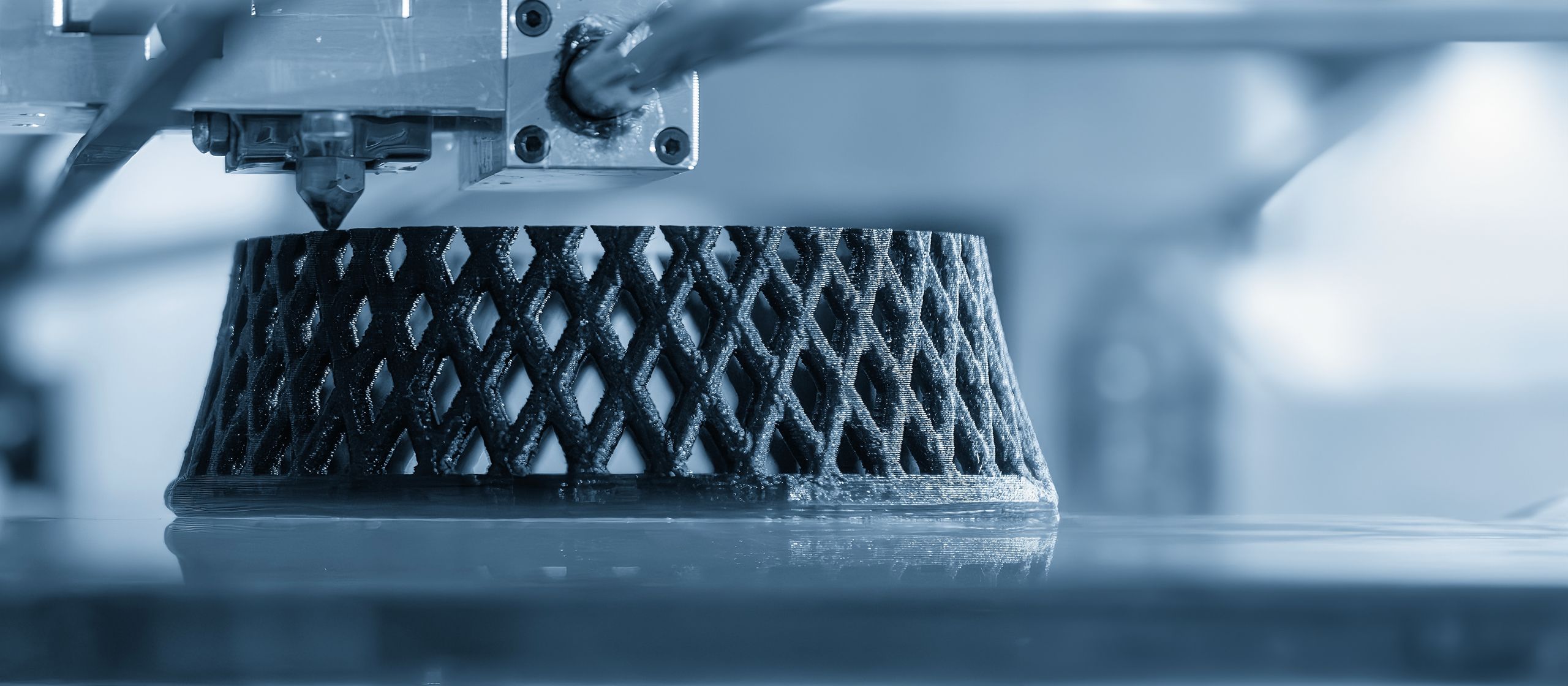

Additive technologies will cut energy sector downtime

Unplanned downtime in the energy sector carries high costs for operators and, in extreme cases, can even disrupt power supply. This downtime often results from delays in securing essential components for industrial machinery. With 3D additive technologies, including printing and Hybrid Laser Metal Deposition (LMD), complex components such as pump impellers, gas and steam turbine parts can now be produced in a matter of days, enabling customised part recreation for retrofitting existing equipment and supporting reliable, sustainable operations. By 2025, I anticipate that various forms of additive manufacturing will be transformative across a range of sectors, including oil, gas, and nuclear, which require vital parts swiftly to maintain a consistent energy supply.

Pharic Smith, head of engineering at Sulzer Services EMEA

15

Additive technologies will cut energy sector downtime

Unplanned downtime in the energy sector carries high costs for operators and, in extreme cases, can even disrupt power supply. This downtime often results from delays in securing essential components for industrial machinery. With 3D additive technologies, including printing and Hybrid Laser Metal Deposition (LMD), complex components such as pump impellers, gas and steam turbine parts can now be produced in a matter of days, enabling customised part recreation for retrofitting existing equipment and supporting reliable, sustainable operations. By 2025, I anticipate that various forms of additive manufacturing will be transformative across a range of sectors, including oil, gas, and nuclear, which require vital parts swiftly to maintain a consistent energy supply.

Pharic Smith, head of engineering at Sulzer Services EMEA

16

The rail industry will unlock new projects, but with limited funding

The rail sector's biggest challenge in 2025 is delivering more with less money. Great British Railways will start to take shape, showing how the government plans to unify track and train, reform ticketing, and nationalise passenger operators. Rising ticket prices, passenger experience, and continued strikes will remain central issues. Despite budget constraints, critical projects like HS2 and the TransPennine Route Upgrade are progressing. Still, the future of rail investment remains uncertain. The changes to the public funding model present opportunities to unlock 'new projects', but whether transport and rail are at the top of the agenda is yet to be seen. The government and the transport secretary, in particular, must address this urgently to stop the industry grumbling. For 2025, I predict we’ll see the above two take main stage but also a call for accelerated adoption of digital tools to improve our transport network and passenger experience, which continues to be the primary source of frustration for commuters and weekend travellers.

Jonathan Edwards, EMEA market development leader (GHD)

16

The rail industry will unlock new projects, but with limited funding

The rail sector's biggest challenge in 2025 is delivering more with less money. Great British Railways will start to take shape, showing how the government plans to unify track and train, reform ticketing, and nationalise passenger operators. Rising ticket prices, passenger experience, and continued strikes will remain central issues. Despite budget constraints, critical projects like HS2 and the TransPennine Route Upgrade are progressing. Still, the future of rail investment remains uncertain. The changes to the public funding model present opportunities to unlock 'new projects', but whether transport and rail are at the top of the agenda is yet to be seen. The government and the transport secretary, in particular, must address this urgently to stop the industry grumbling. For 2025, I predict we’ll see the above two take main stage but also a call for accelerated adoption of digital tools to improve our transport network and passenger experience, which continues to be the primary source of frustration for commuters and weekend travellers.

Jonathan Edwards, EMEA market development leader (GHD)

17

Sensor technology will make workplaces safer

Smart sensor technology continues to help systemise previously manual tasks, for example, legionella risk detection. Real-time data collection can monitor and take action when water systems require flushing, providing real-time response in support of compliance management. Workplaces may also see a continued shift towards more proactive health and safety technology. For example, novel technologies like electronic charge-based Needlepoint Bipolar Ionisation in HVAC systems can ionise and filter out particles and kill pathogens, supporting better employee health and wellbeing.

Matt Kent, director of engineering at EMCOR UK

17

Sensor technology will make workplaces safer

Smart sensor technology continues to help systemise previously manual tasks, for example, legionella risk detection. Real-time data collection can monitor and take action when water systems require flushing, providing real-time response in support of compliance management. Workplaces may also see a continued shift towards more proactive health and safety technology. For example, novel technologies like electronic charge-based Needlepoint Bipolar Ionisation in HVAC systems can ionise and filter out particles and kill pathogens, supporting better employee health and wellbeing.

Matt Kent, director of engineering at EMCOR UK

18

AI and machine learning will hit the factory floor

As AI and machine learning (ML) technologies continue to evolve, it is crucial that organisations recognise AI as a way to introduce greater efficiencies into existing processes, while also identifying challenges on the factory floor that could be improved.

These advanced manufacturing technologies have quickly become essential tools for optimising the manufacturing process. For example, manufacturers can deploy AI and ML for predictive maintenance, which detects and alerts manufacturers to potential failures in their equipment so that they can be resolved with minimal downtime. AI and ML algorithms also support quality control and can provide insights into process optimisation to make the manufacturing process faster and more efficient.

AI/ML-based defect detection systems will continue to use deep neural networks to detect defects that cannot be seen by conventional visual systems or human inspectors. This streamlines inspection processes, resulting in greater efficiency performance while optimising factory floor space by making room for other lines and solutions through the elimination of legacy inspection stations.

Murad Kurwa, VP, of advanced manufacturing engineering at Flex

19

Construction will build sustainable momentum

The construction industry requires transformative change. The sector can no longer accept lowest cost or lowest quality forms of delivery, nor only consider operational performance standards.

As one of the largest global net importers of timber products, the UK requires new knowledge to improve the localised supply chain, maximise return from reclaimable resources, and develop sustainable supply chains for biogenic crops such as hemp, straw, mycelium and timber.

2025 won’t herald this transformative change in its entirety, but with the launch of the Timber In Construction Roadmap (TICR) in late 2024, and the new government’s wish to delivery 1.5 million houses in the next parliament, combined with net zero carbon targets, there will be moves towards more sustainable forms of construction.

So I think 2025 will see a building of momentum towards a whole system approach that goes beyond net zero, embracing circularity and taking a full view of the broader environmental impact, such as extraction and the effect on biodiversity.

To build such momentum requires critical mass, which can only be achieved through collaboration and connected networks. Such momentum can be the stimulus for a cultural shift in construction, approaching new methods and regenerative approaches that don’t impinge on the climate or ecological systems in the same way as they do today.

Professor Robert Hairstans, director of the Centre for Advanced Timber Technologies (CATT)

19

Construction will build sustainable momentum

The construction industry requires transformative change. The sector can no longer accept lowest cost or lowest quality forms of delivery, nor only consider operational performance standards.

As one of the largest global net importers of timber products, the UK requires new knowledge to improve the localised supply chain, maximise return from reclaimable resources, and develop sustainable supply chains for biogenic crops such as hemp, straw, mycelium and timber.

2025 won’t herald this transformative change in its entirety, but with the launch of the Timber In Construction Roadmap (TICR) in late 2024, and the new government’s wish to delivery 1.5m houses in the next parliament, combined with net zero carbon targets, there will be moves towards more sustainable forms of construction.

So I think 2025 will see a building of momentum towards a whole system approach that goes beyond net zero, embracing circularity and taking a full view of the broader environmental impact, such as extraction and the effect on biodiversity.

To build such momentum requires critical mass, which can only be achieved through collaboration and connected networks. Such momentum can be the stimulus for a cultural shift in construction, approaching new methods and regenerative approaches that don’t impinge on the climate or ecological systems in the same way as they do today.

Professor Robert Hairstans, director of the Centre for Advanced Timber Technologies (CATT)

20

Pop up production will make industry more agile

As we approach 2025 and beyond, manufacturers will need to remain agile and react to an ever-changing landscape. In particular, digital and automation technologies will enable industry to embrace agility like never before. For example, using digitally driven ‘pop-up’ production cells with automation, manufacturing capability can be rapidly deployed. They can even be remotely-controlled to produce high-value and superior products anytime, anywhere.

This concept of ‘pop-up’ production cell is being further developed for more complex processes, such as recovering critical materials from batteries for reuse, or cost-effective production in low volumes to unlock supply chains - as shown in our Factory In A Box. What’s more, this smart and agile manufacturing method can be augmented with AI to optimise production process and minimise waste, helping UK industry to remain globally competitive.

Joe Darlington, director of technology & engineering at MTC

20

Pop up production will make industry more agile

As we approach 2025 and beyond, manufacturers will need to remain agile and react to an ever-changing landscape. In particular, digital and automation technologies will enable industry to embrace agility like never before. For example, using digitally driven ‘pop-up’ production cells with automation, manufacturing capability can be rapidly deployed. They can even be remotely-controlled to produce high-value and superior products anytime, anywhere.

This concept of ‘pop-up’ production cell is being further developed for more complex processes, such as recovering critical materials from batteries for reuse, or cost-effective production in low volumes to unlock supply chains - as shown in our Factory In A Box. What’s more, this smart and agile manufacturing method can be augmented with AI to optimise production process and minimise waste, helping UK industry to remain globally competitive.

Joe Darlington, director of technology & engineering at MTC