Engineering out the ‘world’s most potent greenhouse gas’

Sulphur hexafluoride (SF6) plays a vital role in electricity infrastructure, including substations for offshore wind turbines. It is also the world’s most potent greenhouse gas. Efforts are under way to replace it – but finding a more sustainable option is no easy task

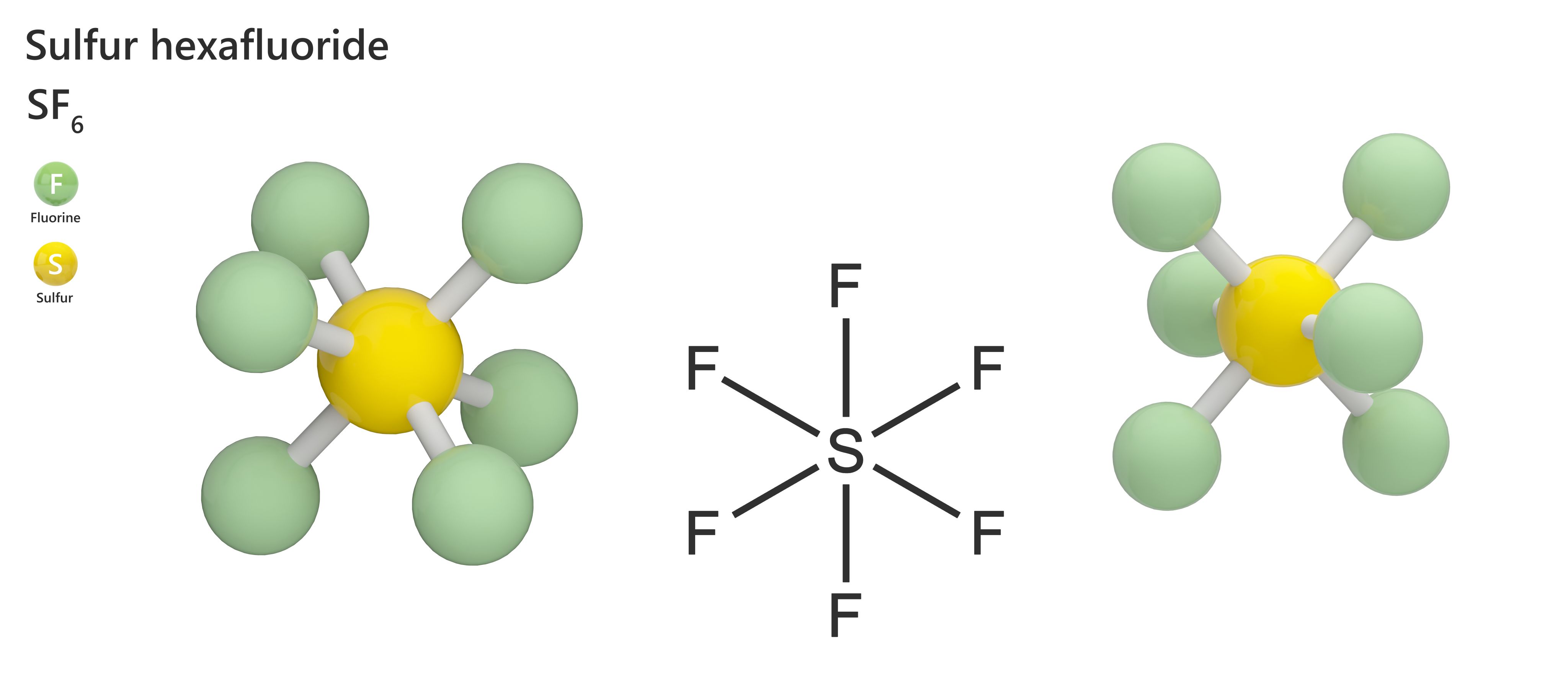

Sulphur hexafluoride (SF6) is a colourless, odourless, non-flammable, non-toxic and highly stable gas. It also has a global-warming potential (GWP) 23,500 times worse than carbon dioxide (CO2), making it the world’s “most potent greenhouse gas,” according to the Intergovernmental Panel on Climate Change (IPCC).

It has high atmospheric stability, traps infrared radiation and has an atmospheric lifetime of 3,200 years, considerably longer than the hundreds of years that CO2 can circulate. Annual emissions rose 24% between 2008 and 2018, according to the National Grid, largely spurred on by use in developing countries – although the true amount could be much higher, as tracking leaks is difficult.

In 2018, 9,040 tonnes were emitted, says National Grid. That is the equivalent of the greenhouse-gas emissions from 44 million passenger vehicles driven for one year, according to Forbes, or 103 million tonnes of coal being burned.

Given its potentially huge contribution to climate breakdown, many historical uses have now ended. It has been used in metal smelting, and to fill double-glazing panels. At one point, it even filled the cushions in Nike Air trainers. One major user has struggled to quit, however.

Electricity infrastructure around the world is still filled with SF6. Fortunately – or unfortunately, depending on how you look at it – it is very good at its job, making it hard to replace in infrastructure that distributes electricity from coal, gas or nuclear power plants.

It is also used in wind energy, preventing overloads in switchgear. While the amounts might be less than in other areas, using such a polluting gas risks a considerable stain on the renewable energy source’s sustainable credentials. Thankfully, some alternatives are being developed.

Arc interruption

Like helium, if SF6 is inhaled it changes the pitch of your voice – but, unlike helium, it makes it very low, thanks to its high density.

Leaks from electricity infrastructure are like thick, sugary squash being mixed with water, says Nina Sasaki Støa-Aanensen, researcher at independent research company Sintef in Norway. “You might get like a bottom layer, something dark and then more watery on the top. But eventually, with time and temperature changes, it will mix to a homogeneous thing, and it will never separate again… eventually, it will use the space available, which is the whole atmosphere.”

Its high density – roughly five times that of air – gives it high dielectric strength, which makes it well-suited for insulation, one of its two main applications in electrical infrastructure. It keeps high voltage separated from the ground, preventing arcing, and enables much smaller switchgear than if air were used, allowing gear to be built much smaller and closer together.

“SF6, technically, is the best you can get. That's why it's been used so much until now,” says Støa-Aanensen.

It is also used as an interrupting gas in circuit breakers, which extinguish arcs of electricity if there is a fault, or if power is being switched from one place to another.

“The circuit breaker has a function of either clearing faults, so if there is a short circuit somewhere, the circuit breaker will protect the system by opening the circuit so there is no current flowing any more – but in doing so, it’ll drag an arc inside it,” says Professor A Manu Haddad, director of the Advanced High Voltage Engineering Research Centre at Cardiff University.

“That arc, to turn it off, you need really a special gas that has these properties of interruption. This is where SF6 is really good.”

Finding compromise

Despite its utility in insulation and circuit breakers, SF6 is increasingly under the spotlight as governments target ‘net zero’ and other sustainability measures. Last year, the European Commission proposed tighter controls on fluorinated greenhouse gases, including a phase-out of SF6 in all new switchgear by 2031.

Companies including ABB, 3M and Hitachi Energy have developed and marketed new gases aimed at filling that gap.

“Depending on the voltage levels that we're talking about, there are different solutions,” says Haddad. “For what we call medium voltage or distribution level, there are solutions that don't have any of the F gases.”

New options include 3M’s Novec gas, which Haddad says came out of research into cooling circuits and fire retardants, and is already being used in switchgear and circuit breakers from ABB and GE.

New solutions have their own drawbacks, however. Novec belongs to the PFAS group of materials, also commonly known as ‘forever chemicals’. Last year, 3M announced it would stop production of PFAS from 2025, amid concern about the impacts on human health and the environment.

Alternatives also have their own GWPs, although they are considerably lower than SF6. Novec has a GWP 1,200 times worse than CO2, says Haddad, although this drops to about 300 when mixed with a buffer gas such as CO2 or nitrogen (N2).

“Nothing has been found that is better technically, so you have to compromise in some way,” says Støa-Aanensen. This might mean having more compact infrastructure with a higher GWP gas, or having bigger infrastructure to balance out lower technical performance.

“It's an exciting time because before you had one solution that was the best. Everyone used it. But now, people choose different solutions with different kinds of scores – so if space is important then you might need to go for this alternative, or if you have all the money in the world, and all the space you need, maybe you go for the air solution.”

Winds of change

Minimising the space used by infrastructure is one of the reasons why SF6 use has been so widespread in wind energy. While the turbines themselves do not normally include the gas, once they generate electricity it goes to a platform substation that does.

“You can't really have an open-air substation, it has to be enclosed. And if you want to enclose it and make it compact, you have to use the gas,” says Haddad. “Or, if there is any switchgear at the base of the wind turbine, then it may contain a smaller amount of gas to insulate the high voltage.”

A few kilograms of SF6 might be used in offshore switchgear, according to Støa-Aanensen, compared to the tonnes that might be used in National Grid substations – but many more are needed to deal with large windfarms, and a few kilograms of SF6 is still equivalent to dozens of tonnes of CO2.

As alternative gases are increasingly adopted, the experts say that they should be suitable for use in wind energy.

Scottish Power Renewables’ East Anglia One windfarm, completed in 2020, already uses SF6-free switchgear for its 102 turbines. The gas-insulated 8VM1 high-voltage switchgear (GIS), supplied by Siemens via Siemens Gamesa, uses vacuum circuit breaker technology, and with clean air instead of SF6 as the insulating medium.

Siemens Gamesa offshore wind turbines

Siemens Gamesa offshore wind turbines

Eliminating SF6 enables climate-neutral generation, transmission and distribution of power, said Siemens Gamesa. The vacuum switchgear also makes it possible to minimise switchgear operation and maintenance costs. Those advantages should make alternatives increasingly attractive as pressure to replace SF6 rises.

High energy

National Grid is also taking the initiative on SF6 replacements – and for good reason. The gas is the single biggest contributor of emissions from the operator, which has committed to halve its SF6 emissions by 2030 and to remove all SF6 from its electricity assets by 2050.

“It's really important for us as a responsible business to look at how we reduce our own carbon emission impact,” says Nicola Todd, head of strategy and innovation for electricity transmission. “Trying to get a gas that provides that same level of performance and can replicate that is really difficult, especially when we're thinking about interrupting high-energy voltage.”

Space-efficient alternatives are particularly important for substations in densely populated areas, such as London

Retrofitting existing infrastructure is another challenge. The operator partnered with Hitachi Energy to use its EconiQTM SF6 replacement in a pilot project at Richborough substation in Kent, eliminating nearly 6 tonnes of SF6 from its high-voltage, gas-insulated switchgear.

“Using this new solution means that we can avoid the environmental impact and cost of replacing equipment, which is otherwise fit for many more years’ service,” says National Grid.

It is also tackling leaks, to prevent SF6 ever reaching the atmosphere. All infrastructure is designed to seal in the gas, but small leaks occur as equipment ages. Repairs also require the gas to be removed before the work is carried out.

“If you have a gas-insulated substation to work at high voltage, you need a lot of little pipes feeding it. If the gas leaks, then you need to renew it, or if you want to do some work you need to recover the gas and open that zone. Those low-pressure or auxiliary SF6 pipes are possibly the worst, because they also leak,” says Haddad.

To tackle the issue, National Grid has tested the use of Molten Metal Manipulation (M3) technology from Rawwater in Cheshire. The M3 process involves the use of either a ‘leak extinguisher’ alloy spray, or an easily deployed ‘CollarCast’, where molten alloy is cast into a custom-made, reusable mould. Both techniques are relatively low temperature and require no curing time.

Rawwater leak technology

Rawwater leak technology

The operator tested the M3 alloy spray in difficult-to-access areas, while the CollarCast process was used to ‘heavily mitigate’ flowing N2 leaks – used to simulate SF6 – at pressures of up to 7bar, without the need for a system outage.

Works are particularly challenging in areas with high wind generation and renewables connected to the grid, says Todd. “Outages might impact the ability to use that renewable energy. What this technology allows us to do is to deploy it while the system is still live.

She adds: “There's a lot of research and development in this area that we're involved in. It's important that we're all taking the right steps and sharing what we learned, so that we can make sure we're all reducing our overall emissions.”

Stemming the flow

Stopping leaks before they happen will also play a central role in reducing the impact of SF6 on our environment. Separated ‘gas zones’ allow fixes on individual parts without leaking all of the gas from a substation, says Haddad, while better ‘O’ rings ensure less leakage.

“The equipment is tighter and the leakage is lower. In the past, gas-insulated equipment made 50 years ago, they leak badly because the technology was not as good as today. But now that leakage, even for SF6, is reduced significantly, and the technology of containing the gas inside the equipment has improved,” he says.

Leak management and current SF6 alternatives offer a temporary solution, he adds, until options with even lower GWP are developed.

Increasing demand for energy means the work is more important than ever, says Støa-Aanensen. “We want to have more and more equipment, so the sooner the manufacturers stop making SF6 equipment, the better.”

“I don't think it's an option to say, ‘OK let’s just not expand the grid’. Because the options are also not great, right, we still want to have electricity… it's difficult, because SF6 is bad, but it’s also about making sure we have a safe grid.”